At RIVI we are specialists in designing, manufacturing and implementing spray lubrication systems for demanding industrial environments. Our technology is geared towards maximising the operational efficiency of your production processes, protecting your critical assets and reducing premature wear of critical components.

This type of system stands out because of its ability to apply a precise and controlled lubricant film on specific areas such as gears, chains, bearings or sprockets, even under extreme conditions of temperature, humidity or speed.

Why go for a RIVI spraying system?

- Because you guarantee precise lubrication in real time.

- Because you optimise the consumption of fat or oil, avoiding excesses or waste.

- Because you protect your investment in machinery in a professional and systematised way.

Our experience in the industrial lubrication sector allows us to offer you solutions with technical guarantees and a focus on results. If you are looking to improve productivity, reduce unplanned downtime and extend the life of your machinery, this technology is the right choice.

Spray lubrication equipment

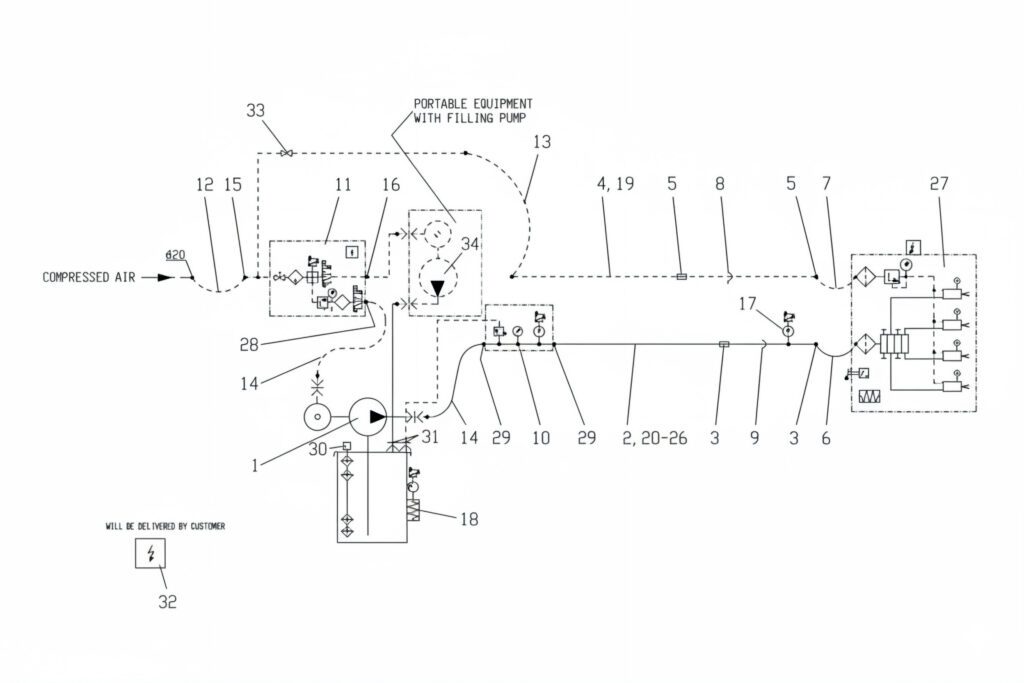

The RIVI spray lubrication equipment are designed to be integrated into any production line with reliability, safety and precision. Each of our components meets high technical standards and is adapted to the customer's actual operation.

Our systems include:

- High precision spray nozzles which ensure optimum coverage without generating unnecessary mist or residues.

- Robust and calibrated feed pumps, They are able to work with oils of different viscosities or greases. In addition, they can incorporate tanks or adapt to commercial drums.

- Intelligent control systems which not only allow the lubrication times and quantity of lubricant applied to be regulated, but also provide a comprehensive level of monitoring for maintenance/control personnel.

- Solenoid valves and level and pressure sensors, essential for continuous and safe monitoring of the system.

This equipment is made of materials abrasion and chemical resistant, This makes them ideal for sectors such as the steel industry, cement maker, paper and mining, among others. In addition, they allow a modular and scalable installation, which favours the adaptation to future plant expansions.

Types of spray lubrication systems we offer

RIVI offers a range of adapted technical solutions to different sectors, The following are some of the main characteristics of our products. Our systems and equipment have been developed from real-world experience in industrial environments, allowing us to design solutions that really work where they are needed most.

The main types we manufacture and install include:

- Monitored spray nozzles

- Pumps with tank or adaptable to commercial drums

- Monitoring and control panels

In each of these cases, our technical team carries out a preliminary study of your needs, ensuring that the proposed solution is effectively integrated into your operations.

Our grease or oil spraying system

RIVI has developed a spraying system robust, versatile and technically superior, compatible with both oils and greases. This flexibility allows it to cover a very wide range of applications, from heavy machinery to high precision automated processes.

Some of the distinguishing features of our system are:

- Individually monitored nozzles, capable of spraying grease particles without clogging, providing real-time operational control.

- Compatibility with greases of different consistency (up to NLGI 2), This makes it a valid solution for multiple industries.

- Optimised working pressure, adjustable according to the characteristics of the lubricant and the surface to be coated.

In addition, we offer the possibility to integrate this system with remote control platforms or SCADA systems, The new system provides complete traceability of the greasing process. This provides a clear competitive advantage for industries requiring regulatory compliance, internal audits or continuous quality control.

Investing in our system ensures consistent performance, intelligent lubrication and real life extension of every component in your production line. In fact, these systems can be integrated into existing centralised lubrication installations, whether single, dual or multi-line. This versatility allows you to expand capacities without changing the main structure of the system, facilitating an efficient transition to more controlled and precise lubrication.

The right implementation makes all the difference. That's why at RIVI we not only design and supply the systems, but we also guarantee its safe, efficient and tailored to your operational reality.

Our team of specialised technicians will come to your premises to make:

- Customised technical study, analysing the specific needs of machinery, environmental conditions and type of lubricant.

- Professional installation of the complete system, The range of products includes everything from the attachment of nozzles to the connection of sensors and control units.

- Verification of technical parameters, including pressure calibration, spray testing, leak testing and synchronisation with duty cycles.

As for the maintenance, RIVI proposes plans adapted to the criticality of your production. We take care of:

- Review periodic inspection of nozzles, filters, solenoid valves and sensors.

- Cleaning and replacement of worn elements.

- Evaluation and adjustments in programming.

With our services, you assure the continuous operation of your lubrication system and avoid unplanned downtime that can lead to significant losses. Our technical approach is based on prevention, constant control and continuous improvement.

Request a quotation for your spray lubrication equipment

If you want to implement a high-performance industrial lubrication solution, we invite you to contact RIVI to request a technical study and a personalised quote. Our sales team will advise you in a transparent and professional manner, taking into account:

- The characteristics of your machinery and industrial sector.

- The type of lubricant currently in use.

- Area of application and required consumption.

- Particularities of each case.

Once this information has been collected, we developed a detailed proposal, We will provide you with a technical and functional assessment, so that you can evaluate the operational and economic advantages of our solution.

With RIVI, you don't just buy a piece of equipment: you implement a solution reliable, safe and designed to last.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions on spray lubrication

We understand that a technical decision requires clear and substantiated information. For this reason, we resolve the following questions most common doubts related to spray lubrication systems. This section is designed to help you assess with confidence whether this technology is suitable for your production environment.

How does a spray system distribute lubricant?

The lubricant is distributes using classical technical systems (progressive, double line, etc...) to be dosed by means of nozzles that project it directly in the lubrication zone.

How is the amount of lubricant sprayed into the system adjusted?

It is regulated by the control system which controls the lubrication cycle control. In this way we guarantee dose exactly what is needed, helpaThe Commission has also taken the necessary steps to reduce lubricant consumption without compromising the protection of the environment. the equipment.

In which applications is it appropriate to use spraying systems?

They are ideal for open gears (pinion-crown gear, pinion-zipper...) and mechanisms without a threaded connection.

Are there different types of nozzles for spraying systems?

Yes, and each one is suitable for different lubricants, pressures of work, areas of application and, about all, ahe level of monitoring required. At RIVI we select the perfect nozzle for your process, ensuring efficient lubrication from day one.

What are the advantages of RIVI's spray lubrication systems?

They bring precision, savings, easy integration and operational reliability. With RIVI, you implement a technical solution that protects your machinery, optimises resources and improves your industrial results from the first use.