At RIVI, We understand that every second of downtime on a production line represents a direct loss to your company. That's why our single line lubrication systems are designed with one goal in mind: to ensure the continuous, accurate and efficient operation of your industrial machinery.

These systems are designed to dosing lubricant with total uniformity through a single conduit, allowing you to keep all moving parts of your machinery properly lubricated, without constant manual intervention. The result is a significant reduction in mechanical wear, optimisation of lubricant consumption and a noticeable improvement in operational productivity.

With decades of technical experience, RIVI works with engineering companies, industrial operators and maintenance managers who demand reliability, precision and robustness. Our catalogue of simple online solutions meets the most stringent requirements of industries such as automotive, food, paper, textile, mining, metallurgy and many others.

Single line lubrication equipment

The single line lubrication equipment RIVI's modular design allows for quick integration into new and existing machinery. Thanks to their modular structure, they can be quickly integrated into both new machinery and existing installations.

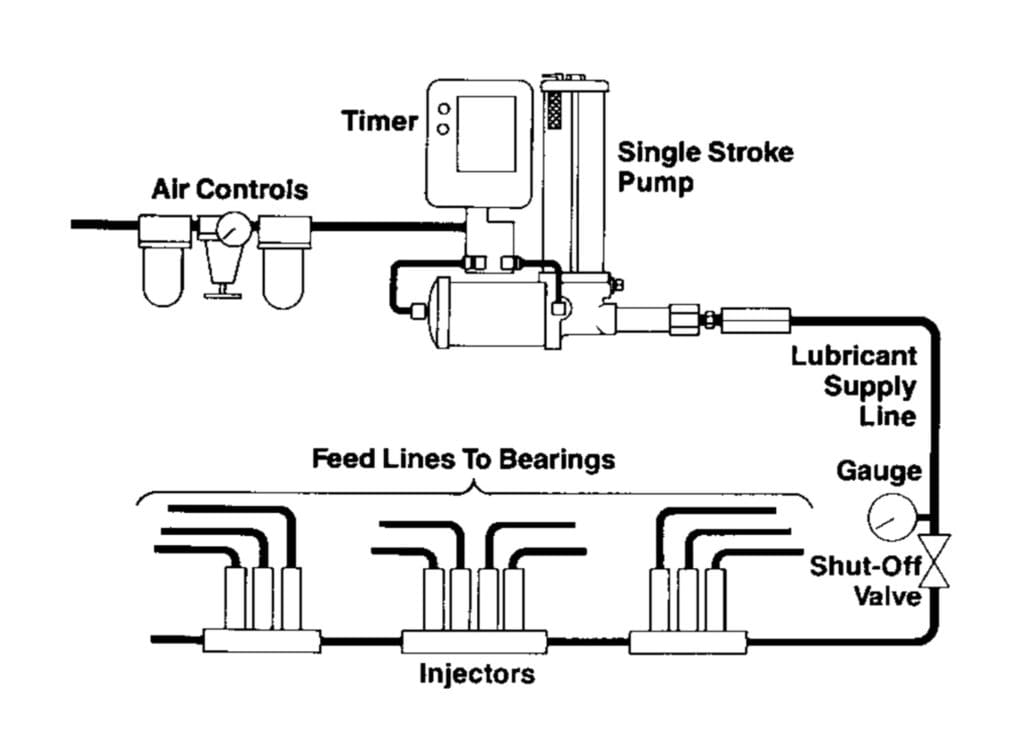

This equipment consists of a lubricating pump which feeds lubricant through a main line to a series of volumetric dispensers. Each dispenser delivers precisely the required amount of lubricant to each critical point of the machinery. This system ensures constant lubrication, with adequate pressures, without excesses or shortages, which extends the service life of bearings, guides, gears and other mechanical elements.

At RIVI, we offer versions fully automated, tailored to the specific industry. Our systems can be connected to switchboards, pressure or flow sensors, PLCs and SCADA systems, allowing you to monitor their operation and prevent faults before they occur.

In addition, the simplicity of the design facilitates installation, servicing and maintenance. This results in less operator dependence and less maintenance. substantial cost reduction associated with corrective maintenance. This is a continuous consumption lubrication system, in which the points receive fresh doses of lubricant at each cycle, with no return. This feature ensures constant and reliable lubrication, ideal for applications where permanent wear protection is required, even on machinery with long operating periods.

Types of single line lubrication we offer

At RIVI we do not work with generic solutions. Our approach is based on analysing the specific needs of each customer and offering the single line system that really adds value to the production process. Our range includes some of the following examples:

- Programmable automatic systems: ideal for large industrial lines or critical machinery. These systems feature timers, level sensors, electronic controllers and programming options that allow lubrication cycles to be set according to actual workload.

- Systems with integration to centralised control (PLC): designed for industries that already operate with automation systems. These systems communicate directly with the customer's control network, allowing alarms, consumption and lubrication times to be displayed in real time.

- Systems for vehicles and mobile machinery: adapted to extreme conditions and dynamic environments. Whether for agricultural, forestry, construction or heavy transport machinery, these systems ensure reliable and continuous lubrication during operation.

Each system we design is subject to rigorous quality controls and can be configured according to the viscosity of the lubricant, the distance between points, the number of outlets, the operating temperature and the type of industrial application.

Centromatic Single Line System

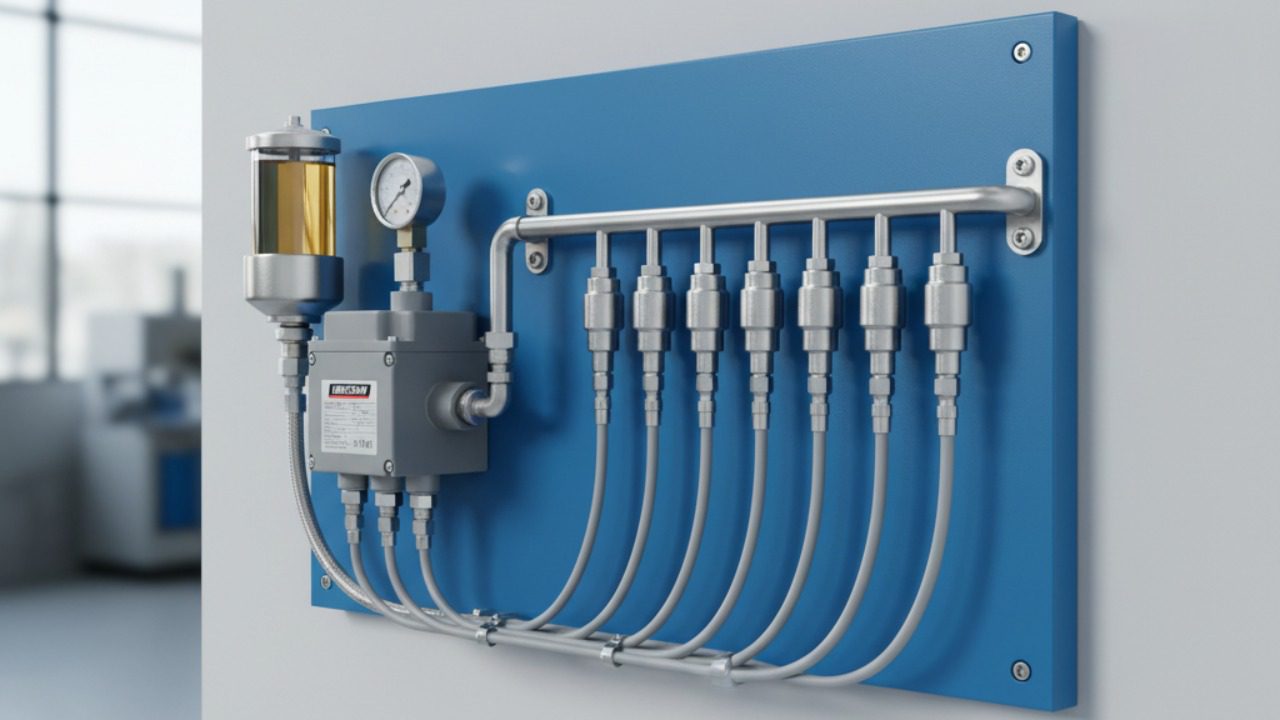

He RIVI Centromatic system is synonymous with precision, reliability and efficiency. It is a volumetric centralised lubrication system, based on single-line technology, specially designed to maintain multiple lubrication points active with a single impeller.

This system stands out for its ease of maintenance, modular expandability and excellent performance under demanding conditions. It is successfully used in sectors such as mining, public works, steel industry, automotive and continuous process machinery.

Some of the key benefits of the Centromatic system are:

- High-performance metering dispensers: allow precise adjustment of the amount of lubricant that each point receives. This ensures that the most critical components receive the exact volume they require, no more and no less.

- Robust design: constructed of materials resistant to corrosion, vibration, extreme pressure and harsh environmental conditions.

- Smart components: pressure sensors, flow indicators, fault alarms and feedback options to the control system.

- Easy maintenance: its structure allows quick access to key components, facilitating inspection and replacement.

In addition, the system dispensers Centromatic feature built-in visual indicators, allowing the lubrication cycle to be checked quickly and easily. Their design also allows the nozzles to operate at large distances from the point of delivery, maintaining flow accuracy without loss of performance, which is ideal for large production lines or machinery distributed across multiple locations.

Installing a Centromatic system is a strategic decision for any company that wants to reduce wear and tear on its machinery, minimise downtime due to mechanical failure and maintain technical control of lubricant consumption.

At RIVI, we don't just sell equipment. We accompany our customers throughout the entire life cycle of the system, from pre-engineering to commissioning and subsequent maintenance. Our technical team is able to carry out the following tasks professional installations of single-line volumetric systems in complex environments and active production lines.

Each installation is based on a personalised technical diagnosis it takes into account:

- Type of machinery.

- Location of lubrication points.

- Lubricant type and viscosity.

- Environmental operating conditions.

- Level of automation required.

From there, we designed and installed a efficient and scalable system, using only highly reliable components. The process is fast, safe and respectful of the customer's operations.

In addition, we offer preventive maintenance plans aimed at ensuring continuity of service. We perform regular inspections, spare parts, recalibrations and performance analysis to help prevent failures, reduce operating costs and extend system life.

Request a quotation for your single line lubrication equipment

At RIVI, we know that each client has specific needs. That is why we offer you services of personalised advice, with specialised technical support, to help you choose the right single line lubrication equipment that best suits your industrial activity.

You can contact our technical-sales team whenever you need to. We will study your case and draw up a adapted proposal, from both a functional and operational point of view. Our goal is to help you optimise processes, reduce costs and ensure the longevity of your industrial assets.

Rely on a supplier who knows first-hand the challenges of industrial lubrication. With RIVI, you take a step ahead in reliability, precision and control.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions on single line lubrication

To help you better understand how these systems work and how they can be integrated into your operating environment, we have compiled some of the most frequently asked questions we receive at RIVI. Our technical team responds with the precision and clarity that we are known for.

How does a single line lubrication system work?

It works by means of a pump that pushes the lubricant through a main line, by pressurising it and causing the volumetric dosing units to actuate.. The circuit is then depressurised and ready for a new cycle.

What type of machinery is compatible with single line lubrication systems?

They are compatible with virtually any type of industrial machinery that requires constant greasing at multiple points, whether stationary or mobile.

In which industrial sectors are single-line lubrication systems typically used?

They are used in sectors such as automotive, food, metallurgy, agriculture, mining, paper and textile, among other environments where the type of lubricant takes on an important role.

What is the main characteristic of single-line systems?

Its main feature is the simplicity of the design: a single main line feeds all lubrication points with precision and uniformity.

What are the benefits of choosing a RIVI single line system?

It offersmos precision, durability, maintenance simple, easy to extend the circuit, protection of the lubricant as it is depressurised most of the time and adaptability to different industrial applications with specialised technical support.