Oil-based varnish removal technology

RIVI » Lubrication systems » Oil-based varnish removal technology

At RIVI for more than three decades we have been designing and manufacturing industrial lubrication and greasing solutions that guarantee maximum reliability in demanding production environments. One of the most critical problems facing modern plants is the formation of varnish in lubricating and hydraulic oils. This phenomenon degrades the efficiency of equipment, causes valve and bearing failures, and drastically reduces the service life of machinery.

He varnish behaves as an insulating layer that traps heat and restricts oil flow in small clearances, exacerbating wear and loss of efficiency in sensitive systems.

Aware of this challenge, we have developed solutions for the removal of oil-based varnish that not only solve the problem, but also turn it into a competitive advantage for your company. Investing in these solutions is to ensure productive continuity, avoid unplanned downtime and optimise the use of your resources. At RIVI we are not talking about a simple technical service, We are talking about a business strategy based on reliability, sustainability and profitability.

In addition, since 2019 RIVI is official distributor in Spain of Fluitec, We are a leading company in solutions for varnish control and removal, which allows us to offer the most advanced and proven technology on the market.

Varnish removal technology for lubricating oils

The lubricating oils are the first line of defence for any industrial equipment. However, when the varnish accumulates, The risks are multiplied by the fact that they no longer fulfil their protective function. At RIVI we know that the key is not only to replace oils, but to implement advanced solutions capable of keeping them cleaner for longer.

Our technology for the removal of varnish on oils lubricants act at three fundamental levels:

- PreventionPrevent the formation of varnish at source, controlling the oxidation and degradation of the oil.

- CorrectionRemoves deposits already formed on critical components, restoring equipment performance.

- OptimisationExtends the life of lubricants, reducing the need for changes and associated costs.

By relying on RIVI, your plant obtains a technology partner which guarantees oils in optimal conditions and equipment always working at maximum capacity.

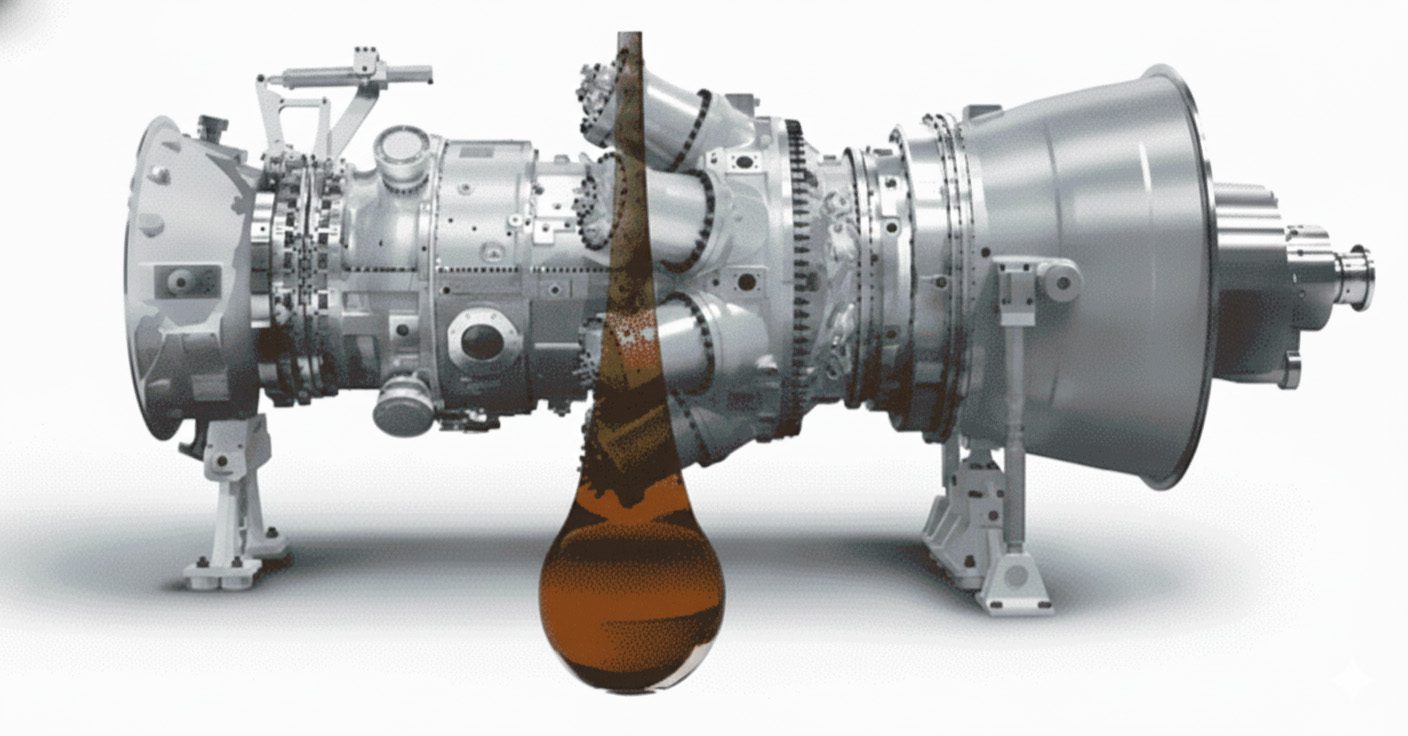

Varnish removal on rotary equipment

Rotating equipment such as turbines, compressors or hydraulic pumps are particularly sensitive to the effects of varnish. A thin film of deposits on valves or bearings can reduce the efficiency of the equipment, alter the working pressure and compromise the safety of the entire installation.

The rotating equipment are, in fact, the usual victims of varnish due to the harsh operating conditions to which they are subjected, which makes the varnish control The reliability of the system is a decisive factor in its reliability.

At RIVI we have designed specific solutions that remove these varnishes even during in-line operation, no need to stop production. This represents a crucial advantage: your company avoids downtime losses, while ensuring the reliability of your most critical equipment.

With our technology, rotating equipment achieves greater stability, responds precisely to process demands and extends its service life, resulting in direct savings and a more competitive operation.

Filters for varnish removal

A common misconception is that conventional filters are sufficient to stop varnish. In reality, they only capture large particles, while the varnish precursors circulate freely in the oil. That is why we at RIVI have developed specialised high-efficiency filters, capable of trapping pollutants at the molecular level.

Among its advantages stand out:

- Continuous operation without the need to stop the plant.

- Removal of soluble and insoluble compounds that cause varnish.

- Protection of valves and precision components against microscopic deposits.

With these filters, the oil remains consistently clean, making the lubrication system a reliable partner for large-scale production.

The hydraulic oils play a fundamental role in sectors such as in the steel, petrochemical and power generation industries. However, they are extremely sensitive to varnish build-up, which can cause everything from blockages in servo valves to slowdowns in control systems.

At RIVI we offer varnish removal technology for hydraulic oils that act directly on the fluid chemistry, restoring its original properties and preventing deposits from affecting the precision of hydraulic movements. With our technology, your equipment not only regains its responsiveness, but achieves sustained performance even under the most demanding conditions.

Solubility enhancer DECON varnish control and removal

He solubility enhancer DECON is one of the most advanced tools on the market for the control and removal of varnish in hydraulic oils. This additive has been designed to act in parallel with our filtration systems, increasing the solubility of the oil and facilitating the contaminants to be removed with total efficiency.

Thanks to DECON, your company gets:

- Dissolve varnishes already present in the circuits.

- Hold contaminants in suspension until filtration.

- Reduce premature wear on hydraulic valves and actuators.

The result is a cleaner, more precise hydraulic system with a significantly longer service life. A solution that does not require immediate oil replacement and that integrates seamlessly with the predictive maintenance we implemented at RIVI.

Increased equipment reliability through varnish removal

Varnish removal is not just a technical issue; it is a business strategy to ensure that every hour of your equipment's operation translates into productivity and profit. At RIVI, we understand that unexpected downtime can mean millions in losses. That's why our solutions are designed to increase the reliability of equipment, The new system will ensure that they operate continuously and without unforeseen events.

Our technologies allow:

- Reduce unplanned stops.

- Reduce maintenance costs.

- Optimising the energy efficiency of systems.

By investing in varnish removal, your company not only protects your machinery, it also strengthens your competitive position in the market, ensuring more stable and predictable processes.

Life extension of lubrication and hydraulic oils

Frequent replacement of oils is not a sustainable or cost-effective solution. With our technologies, oils retain their properties for longer, which means a significant extension of its lifespan.

This offers direct benefits:

- Savings on the purchase of new oils.

- Waste reduction and environmental commitment.

- Preservation of the original characteristics of the fluid.

At RIVI we not only help to keep your oils clean, we also help to boost your operational sustainability. A machine that works with oils in optimum condition is synonymous with fewer breakdowns, less consumption of resources and greater profitability for your company.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions on varnish control in lubricants

At RIVI we know that questions about the formation and removal of varnishes in oils are common in companies seeking to maintain their production in optimal conditions. In the following, we solve the most relevant issues so that you have a clear picture and can assess the importance of implementing a specialised varnish control solution.

What causes varnish formation in hydraulic and lubricating oils?

The varnish is produced by the oxidation and degradation of oil subjected to high temperatures and stresses, resulting in solid deposits on critical components. With a RIVI system this process can be effectively controlled to avoid breakdowns.

How can the presence of varnish in an industrial oil be detected?

There are visual indications that allow us to intuit the presence of varnish (change of colour in the oil, formation of golden coloured layers on some internal parts of the machine, presence of sludge at the bottom of the tank, increase of vibrations, increase of temperature, ...).

One of the best methods of detection is to perform an analysis by an accredited laboratory and ask for the MPC (MembranePatchColorimetry) value, depending on the value of this result it will be indicative of the potential for varnish formation.

Which industries need varnish control most frequently?

Sectors such as steel, petrochemicals, role, generation energy and automotive are the most exposed. In all of them, RIVI offers adapted solutions that guarantee operational continuity.

What are the advantages of varnish removal technology?

Provides greater equipment reliability, The reduction of unplanned downtime and the extension of the service life of the oils. In short, it ensures a quick and tangible return on investment.

Can varnish removal solutions be installed on an already operational line?

Yes, our solutions are designed to integrate into existing installations without the need for complex modifications, allowing you to start making profits right from the start.