At RIVI, We understand that the operational efficiency of an industrial plant starts with the reliability of each of its components. The progressive lubrication systems are the most effective technical answer to reduce wear and tear of equipment, ensure constant operation and avoid unnecessary stoppages that compromise production, with a moderate investment.

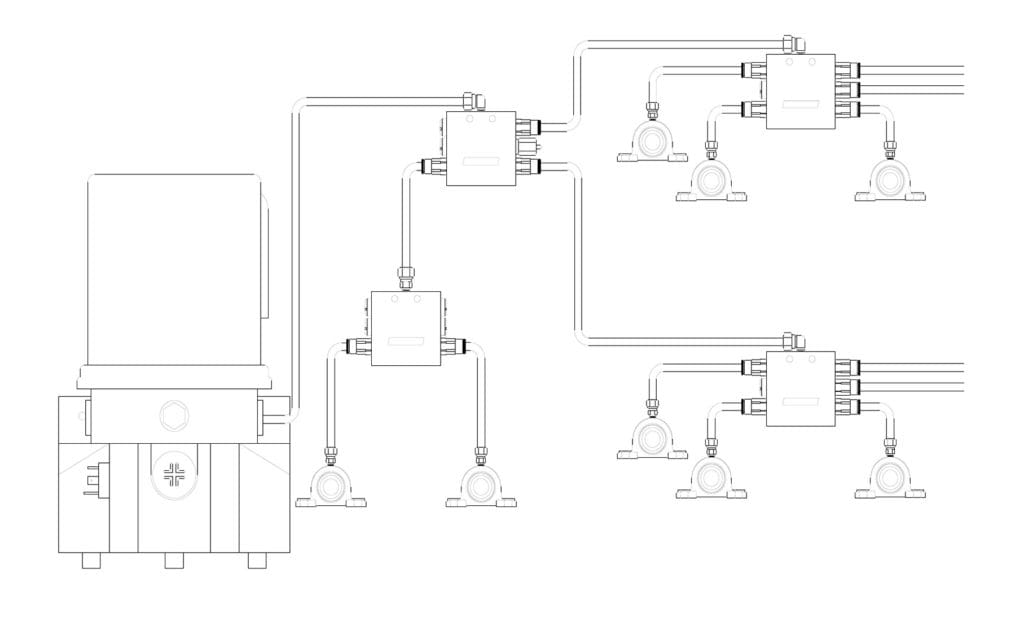

This type of system distributes the lubricant in sequence through a dosing set, feeding each friction point with millimetric precision. The main advantage is clear: each zone receives only what it needs, at exactly the right time, with no waste, no overgreasing, no errors and a very high level of monitoring.

We design and implement progressive systems adapted to industries that cannot afford unforeseen events. If you work in sectors Our equipment is a safe, long-lasting investment with an immediate return on investment in terms of reduced incidents and maintenance.

Progressive lubrication equipment

Our progressive lubrication systems are designed with the latest technology to meet the demands of the harshest industrial environments. At RIVI, we don't just provide components, we provide complete solutions, ready to integrate into your production system and multiply its performance.

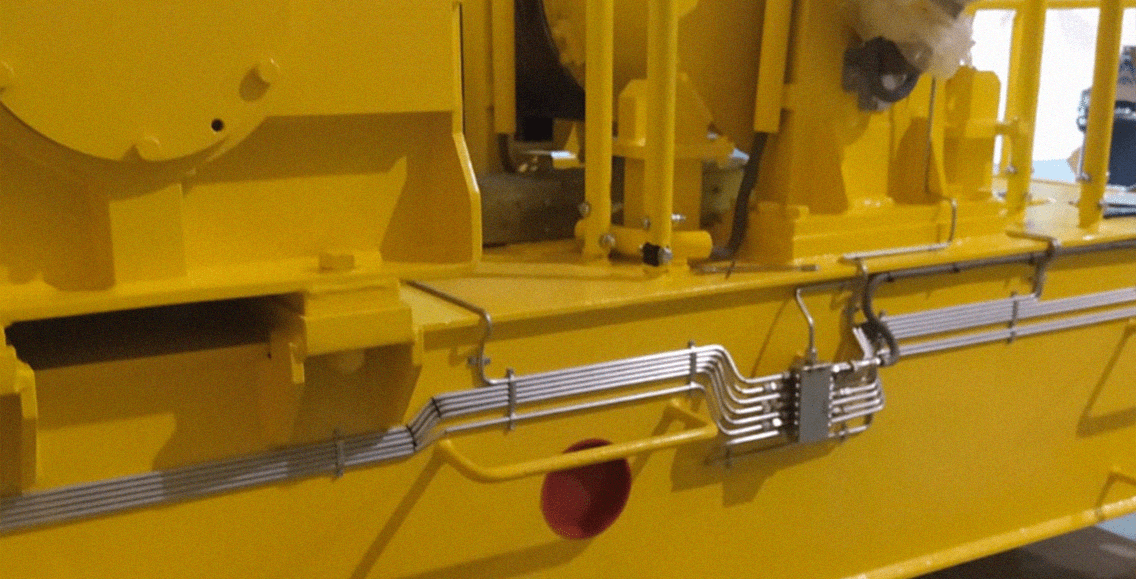

Each unit consists of a central pump, supply lines, metering valves and optional sensors that allow for a integral process control. The system operates automatically and constantly, eliminating the need for manual intervention in hard-to-reach areas. In this type of configuration, the lubricant is distributed sequentially: each point is only lubricated when the previous one has been supplied, thus ensuring progressive, controlled and reliable lubrication.

Our products are differentiated by:

- High precision components, developed to operate with maximum reliability under constant pressure.

- Modularity, The system can be adapted to the specific requirements of your machinery.

- Full compatibility with standard industrial lubricants: NLGI 0 to 2 greases and technical oils.

- Robust design, ideal for demanding industrial environments where temperature, dirt and vibration are critical factors.

- High pressure work, This allows the use of all types of lubricants, even at low temperatures.

With the RIVI systems, you ensure a greasing efficient, homogeneous and continuous at all critical points of your machinery, optimising its lifecycle and drastically reducing corrective maintenance costs.

Types of progressive lubrication systems we offer

We offer a specialised range of progressive lubrication systems that are adapted to the highest standards in the sector. We understand that each industrial plant and each type of machinery has technical particularities that require specific solutions. That is why we develop and install:

- Classic progressive systemsDesigned for installations with independent work areas, where different greasing cycles are required depending on the operating area. Perfect for large industries where control and segmentation are essential.

- Combined systems, electronically controlled: classic progressive systems combined with double line, The lubrication sensors, which can be integrated into industrial automation systems via PLCs or IoT interfaces. This makes it possible to visualise and manage the lubrication status in real time, anticipating possible failures.

- RIVI customised systems% products: developed under particular specifications, designed for machinery with extreme working conditions, high temperatures or exposure to abrasive particles. In these cases, we carry out an exhaustive technical study to guarantee an effective 100 % solution.

With RIVI, you not only get a greasing system, but a functional architecture, designed to increase the operational availability of your facilities.

Our Smart Quicklub progressive system

He Smart Quicklub by RIVI is the ultimate expression of our technical capability and innovation. This progressive system has been designed to meet the requirements of the most advanced industries, integrating automation, sensing and remote control to offer a fully connected and monitored industrial lubrication experience.

Some of the technical characteristics of our Smart Quicklub progressive lubrication system are:

- Intelligent progressive distribution, The system is based on dosing blocks with real time pressure and flow rate detection.

- Continuous monitoring through pressure, flow and lubricant level sensors, allowing full traceability of operation.

- Early fault diagnosis, thanks to its control software compatible with SCADA systems and predictive maintenance platforms.

- Compact and robust design, specific to heavy industry.

- Operation at elevated pressures up to 350 bar, ideal for harsh industrial conditions.

- Visual or electrical control of each stage of the process.

- Possibility of modular extension by means of new dosing blocks without redesigning the installation.

The Smart Quicklub has been successfully implemented in settings where margins of error do not existThe following are just a few examples: robotised assembly lines, industrial cranes, presses, general machinery or continuous processes in the energy sector.

With Smart Quicklub, we offer you a highly technical tool that not only lubricates, but also monitors, reports and optimises the performance of your machinery.

We understand that a correct installation of a progressive lubrication system not only ensures the immediate operation of the equipment, but also makes a difference to the lifetime of the machinery and the long-term efficiency of the plant. That's why we carry out a detailed technical analysis of each operating environment, assessing the mechanical characteristics, operating regime and critical greasing points. Based on this diagnosis, we design a fully adapted system, precisely calibrated to distribute the lubricant where, when and how it is needed, with no margin for error.

Since a blockage in one of the pistons can cause the system to come to a complete stop, it is vital to ensure the correct operation of all the dosing units by means of periodic technical inspections. At RIVI we carry out this control systematically in order to guaranteeing continuity of service and avoid cascading failures.

We don't just replenish lubricant or check connections, we apply technical procedures to check dispensers, pressures, levels and general system behaviour. This preventive and predictive approach enables our customers to maximise the value of their investment, maintain a stable production environment and drastically reduce friction and wear related mechanical issues.

Request a quotation for your progressive lubrication equipment

At RIVI, we believe that every lubrication system must be custom-designed, The customer's needs are determined by the technical objectives, the complexity of the equipment and the operating conditions of each industry. Therefore, when a customer requests a quotation, the first thing we do is to study their specific situation with a technical and efficiency-oriented approach.

This initial analysis allows us to identify precisely what type of progressive system you need, how it will integrate into your existing processes and what configuration ensures maximum performance with minimum intervention.

Our technical-sales team works closely with the customer throughout the entire process, from the initial proposal to the delivery of the final system. This professional proximity ensures that each solution is right-sized, aligned with industry quality standards and ready to deliver sustainable results from day one.

Request a quote take a decisive step towards operational reliability, reduced maintenance costs and improved performance of your industrial machinery.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions on progressive lubrication systems

If you are considering implementing a progressive lubrication system in your industrial machinery, technical questions are bound to arise. That's why we've put together some of the most frequent queries, to guide you in your decision. Our team is available to give you a detailed answer according to the specific needs of your installation.

How does a progressive lubrication system distribute lubricant?

The system does this by means of metering valves connected by level which deliver the lubricant sequentially and progressive to each point. This technique guarantees a constant and uniform distribution. If you need a configuration adapted to your machinery, we can help you to define it.

In which applications is it ideal to use a progressive lubrication system?

It is especially useful in industrial machinery with a number reducido from lubrication points (usually less than 100) and a financial investment contained. Yes you need lubrication systems with these characteristics, our progressive systems are the most efficient option.

What are the advantages of a progressive lubrication system compared to other systems?

Provides full control over the cycles lubrication automaticallya. If you are looking for a reliable and economic, Ask us about the most suitable options for your environment.

How many lubrication points can a progressive system feed?

Progressive systems are recommended for small to medium installations, up to about 100 points, with moderate investment.. In RIVI we design each installation according to the needs to achieve optimum performance.

What maintenance does a progressive lubrication system require?

No requires inspections The system is fully monitored from the control panel. Only visual inspections are recommended to verify the absence of leaks. We can take care of the complete maintenance and guarantee its continuous operation.