At RIVI, we are experts in lubrication engineering. We design and manufacture oil circulation systems that protect the most demanding machinery in sectors such as energy, oil, gas, paper and heavy industry. We know that a lubrication system failure can result in millions of dollars in losses. That's why we offer high-precision, customised and ready-to-integrate solutions in your plant.

Our systems and equipment ensure a continuous, controlled and filtered oil flow. This not only reduces wear and tear and extends the life of your equipment, it also Optimise the overall performance of your production process.. Trust RIVI to keep your operation running with maximum reliability.

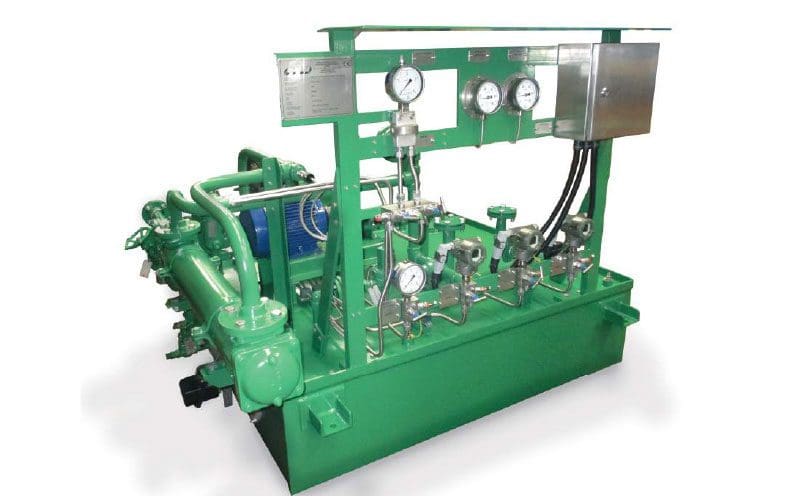

Standard oil circulation systems

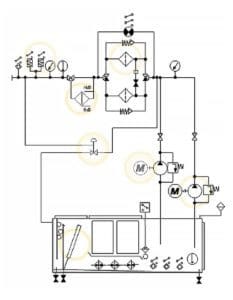

The objective of a oil circulation system is not only to lubricate, but also to dissipate part of the heat generated in the bearings. It is a very sensitive system, which must continuously supply a precise flow of lubricant at a constant pressure and temperature, with a certain degree of cleanliness. The working pressure is normally very low (4 to 10 bar).

A pump sucks oil from the tank, passes it through filters, heat exchangers, etc., and expels it to a distributors or flowmeters which distribute it proportionally and uniformly to the different lubrication points. Subsequently, either through ducts or by gravity, it is returned to the tank from where, once treated, it is recirculated again.

The level of control of these systems usually (and should) be high, because of the importance of its role.

The quality of materials, components, replication / duplication (back-ups), installation, sizing, welding, etc. must be in accordance with the regulations to which they are subject (e.g. API, ASME, etc.), and carried out by specialist personnel.

Our teams follow the ISO 10438 standards, The general requirements for lubrication systems, oil and gas sealing systems, and oil control systems are specified for special applications and general.

In addition, we are familiar with the specifications of the leading engineering companies and manufacturers, The requirements of which are technically demanding.

We have realised teams under American (UL), (TRCU), Canadian (CSA), Asian and Middle Eastern (CSA) standards.

Turbine recirculation system

The turbines require a higher level of technical precision. At RIVI we develop oil recirculation systems for turbines that maintain temperature, reduce vibration and eliminate any possibility of dry contact between internal components.

Our systems incorporate high performance heat exchangers, The system is equipped with electronic flow controllers and condition alarms that anticipate any deviation from the normal behaviour of the equipment. This translates into safer, more stable operations with fewer unscheduled shutdowns.

We work with steam, gas and hydraulic turbines and design tailor-made solutions according to your technical specifications, ensuring seamless integration with your existing lubrication system.

Skid for recirculation in compressors

Premature wear of compressors is often related to poor lubrication. At RIVI we offer recirculation skids fully assembled, tested and ready to install, The bearings and seals are perfectly lubricated under all load conditions.

Our skids include redundant pumps, temperature controllers, automatic regulating valves and fine particle filtration systems. This allows you to keep your compressor in optimum condition, even during long, continuous working days.

In addition, the compact and modular design of the RIVI skids makes them easy to maintain and adapt to small spaces. A safe, long-lasting and profitable investment.

Recirculation equipment for fans

Industrial fans, especially large fans, operate at high speeds for long periods of time. Lubrication failure can lead to production losses and high repair costs. With our recirculation systems, RIVI offers you a reliable solution for maintaining the integrity of the equipment 24 hours a day of the day.

We design each system to maintain a stable operating temperature, The equipment is designed to minimise friction and prevent the accumulation of contaminants. This equipment is prepared to operate continuously in environments with dust, humidity or thermal changes.

Choosing RIVI means protecting the efficiency of your industrial ventilation system and ensuring a safer working environment.

Feed water pump recirculation unit (Feed water pumps)

The boiler feed pumps (feed water pumps) are critical elements in thermal power stations and generation plants. They require a constant, clean and controlled lubrication, Any failure can affect the system pressure and damage the boiler.

Our power plants are built with stainless steel enclosures, dual pumps, purge systems and programmable logic controllers (PLCs). They allow a autonomous lubrication management and offer real-time monitoring of oil status, pressure and temperature.

At RIVI, we don't just design durable systems: we integrate them with your industrial control system for more efficient and safer management.

At RIVI we are aware that many industrial processes require unique solutions. That is why we develop custom-designed special oil circulation systems, The new range of products, which adapt to the most extreme conditions: high temperatures, varying pressures, corrosive environments or space restrictions.

Each special system is designed according to oil type, equipment speed, regulatory requirements (such as ATEX or API) and customer needs.

We integrate technologies such as:

- Double filtration systems for contaminated oils

- Variable frequency drive control (VFD)

- IoT monitoring and remote access

- Components resistant to chemicals or saline environments

- Special solutions developed for our customers, such as:

- Automatic filling trolleys for refineries (ATEX regulation)

- Spraying equipment oil for metal coils

- Advanced filtration systems adapted to each oil type

Investing in a special RIVI system means betting on a solution that adapts to your industrial reality without compromises.

The circulation lubrication system you need

We know that each client has a unique process and that is why we do not sell standard solutions blindly. At RIVI we carry out a personalised study of your plant, we evaluate the equipment that needs lubrication, the operating conditions and your budget, in order to propose you the perfect system for your specific case.

We advise you from the very beginning and accompany you through design, manufacture, installation and maintenance to the final commissioning. Our commitment is not just to make your system work, but also to make you more cost-effective, efficient and competitive.

Do you want to increase the lifetime of your equipment, reduce maintenance costs and avoid unplanned downtime? Talk to our specialists. At RIVI, we have the solution you need.

API 614 and API 610 oil recirculation systems

RIVI designs systems that comply rigorously with the standard API (American Petroleum Institute), The most stringent international standard for turbomachinery lubrication systems. These solutions are aimed at sectors where error is not an option: power generation, refineries, petrochemical plants and the Oil & Gas sector in general.

Our systems meet all the requirements of the standard in terms of design, safety, filtering, redundancy, instrumentation and materials. When you choose RIVI, you choose technical compliance, international support and proven reliability.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

API 610 Circulation power packs

These plants are mainly intended for centrifugal pumps used in critical applications. At RIVI we manufacture units that:

- Ensure a constant supply of filtered oil

- Incorporate high-performance cooling systems

- They have redundant monitoring to avoid unforeseen failures.

- They are designed to operate in demanding conditions 24/7

If your installation requires API 610 compliance, RIVI is your best choice for an accurate implementation with no surprises.

API 614 Circulation centres

API 614 defines the parameters for the design and manufacture of lubrication systems for the Oil & Gas industry (oil refineries, petrochemical, hydrocarbon, etc.).

The RIVI Technical Group has extensive experience in the design and manufacture of systems that must comply with these regulations, as well as with the specific requirements of each engineering OEM, EPCs, and end customers.

API 682 Seal Plans

The sealing plans API 682 are essential to ensure that mechanical seals operate in optimal conditions, avoiding leaks, overheating or contamination. At RIVI we implement the following plans, always selecting the most suitable according to the fluid, pressure and criticality of the process:

- Plan 11Fluid circulation from the pump discharge to the seal. Simple, efficient and widely used.

- Plan 13Fluid return from the bearing to the seal. Improves system stability and controls heat generated.

- Plan 21Recirculation with cooling of the fluid by a heat exchanger before returning to the seal. Ideal for high temperature applications.

- Plan 32The fluid is pumped into the sealing chamber from an external medium. The sealing fluid must be chosen carefully to avoid possible mist and to avoid contamination of the pumped fluid. It is used when the product to be pumped does not have good lubricating properties, contains suspended solids and/or is hazardous.

- Plan 52Double seal system with barrier pressure lower than the process pressure. Uses an external reservoir to maintain lubrication and prevent leakage to the environment.

- Plan 53 AA pressurised external reservoir supplies clean barrier fluid to the sealing chamber. Circulation is via an inner ring. The tank pressure is higher than the pressure of the process to be sealed. Used for «hot» applications or where products have low pressure and are harmful or hazardous.

- Plan 53BThe outer tube supplies fluid to the outer seal in a double seal arrangement. A pressurised diaphragm accumulator supplies pressure to the circulation system. Flow is maintained by an internal pumping ring. Heat is removed by an air-oil or water-oil exchanger. Used in applications where products have high pressures and are harmful or hazardous.

- Plan 54An external pressure system provides the circulation. The pressure in the tank is higher than the pressure in the process to be sealed. Used for applications where products have high pressures and are harmful or hazardous.

-

API 682

-

Plan 54

-

Plan 32

-

Plan 53 A

-

Plan 53B

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions on circulation systems

At RIVI, we know that a lubrication system is a strategic investment. That is why we respond directly to the needs of our customers. frequently asked questions of our clients.

What maintenance does an oil circulation lubrication system require?

Requires regular monitoring of oil condition, pressure, temperature and key components (especially filters). At RIVI we offer preventive maintenance to guarantee its performance and durability.

What warranty do you offer for API lubrication systems and what does it cover?

The guarantee of API systems is their own design.. High-quality, redundant components, typically with Vendor List, ensure extremely high reliability over time.

Can an oil circulation lubrication system help you avoid unplanned downtime?

Yes, The temperature of the machinery is maintained at optimum levels.. On the contrary, any breakdown, failure or unforeseen event in the lubrication system will cause the machinery to shut down.

Is it cost-effective to install an oil circulation lubrication system on an old production line?

Totally. Investing in safe and reliable equipment always pays off..

Does RIVI know how to calculate and design an oil circulation cooling system?

Of course. Our engineers perform the relevant calculations based on specifications and process data to manufacture and design the appropriate oil circulation system for each case.