At RIVI, We understand that the operational efficiency of your machinery cannot be left to chance. That's why we offer solutions for multi-line lubrication systems specifically developed to meet the most demanding technical requirements of the industrial sector. Our range of products guarantees the supply of accurate and reliable of lubricants to multiple lubrication points from a single centralised unit, ensuring consistent protection against wear, friction and temperature extremes.

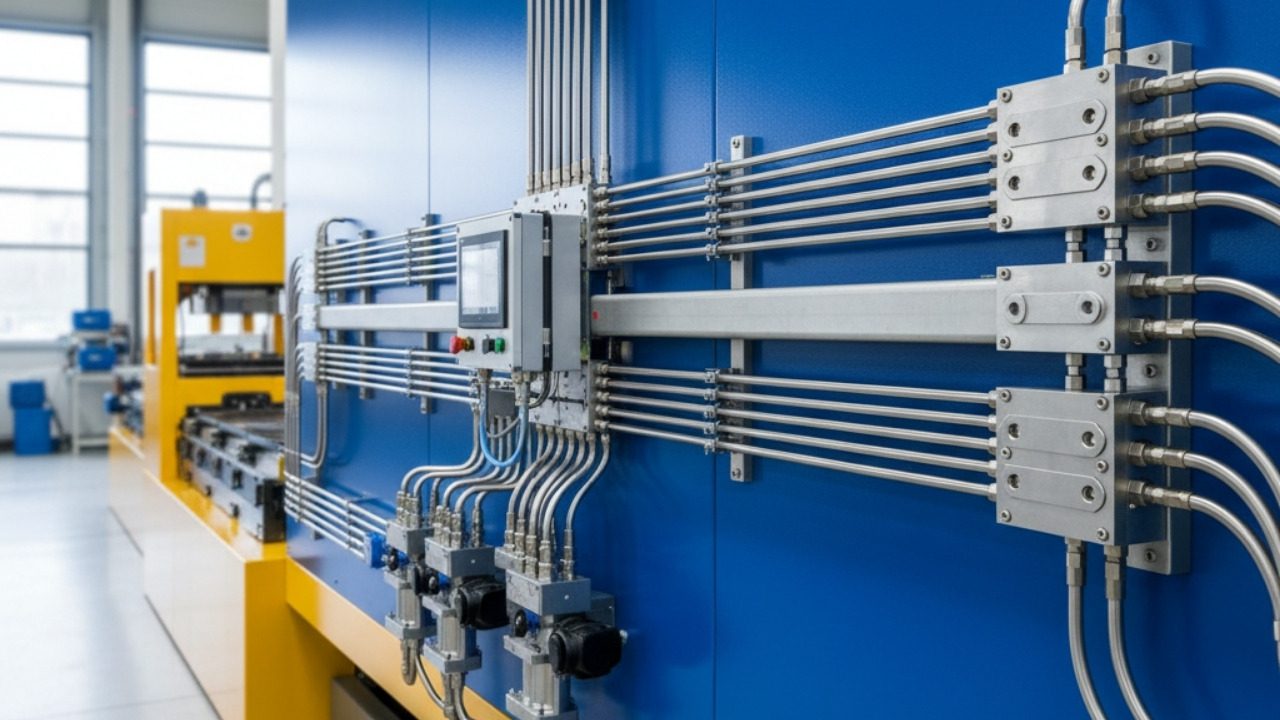

The multi-line systems are designed to integrate efficiently into complex production lines, heavy machinery or equipment operating under severe conditions.

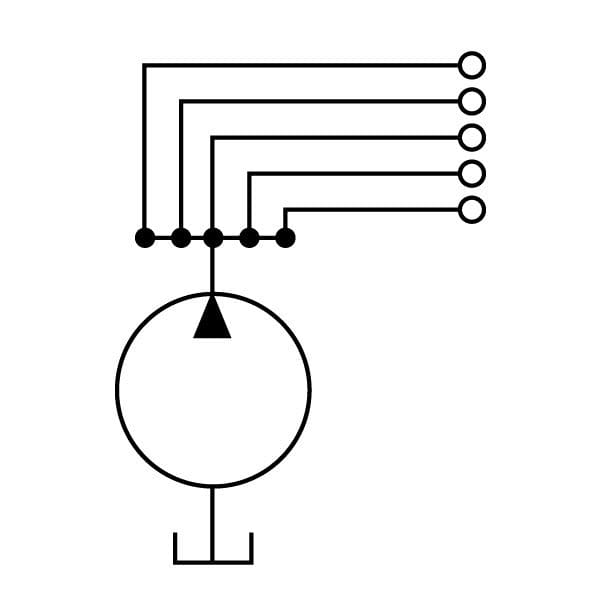

These systems use radial pumps with piston pumping elements arranged around an eccentric shaft. Each piston delivers a metered quantity of lubricant. directly to the connected points, without the need for additional distributors. In addition, when the number of points to be lubricated is high, our multi-line systems can be supplemented with progressive distributors, thus extending their range without compromising the precision and stability of the system.

Thanks to our experience in lubrication systems from high performance, We help to extend the service life of components, reduce unplanned downtime and optimise the cost of operational maintenance.

When choosing a RIVI's multi-line lubrication system, you are investing in technology that is robust, accurate and tailored to the real needs of your production environment. Our commitment is to provide reliable solutions that respond accurately to the challenges posed by your machinery.

Multi-line lubrication systems for industrial machinery

Industrial machinery demands lubrication solutions that are not only technically efficient, but also sustainable in the long term. At RIVI we design and supply multi-line lubrication systems that respond with a high degree of precision to the specific needs of each piece of equipment. These solutions are designed to operate in extreme conditions without compromising performance, even in the harshest industrial environments.

A multi-line system consists of a central pump equipped with multiple outlets each of which distributes lubricant directly to a specific point on the machine. This architecture eliminates the need for secondary distributors and significantly reduces potential points of system failure. The configuration is flexible, allowing the amount of lubricant per outlet to be adjusted, ensuring customised operation depending on the loads, speed or frequency of use of each component.

Our systems are compatible with a wide range of fats and oils (even with solids in suspension such as graphite, Teflon or others...), and are prepared for integration with sensors, control valves and remote monitoring devices. On sectors such as automotive, mining, paper or energy, this technology ensures superior performance without sacrificing operational simplicity.

In addition, every system we market at RIVI is pressure, flow and performance tested to ensure optimal operation from day one. We work closely with our industrial customers to customise each solution, ensuring its effective integration into existing production lines.

At RIVI we do not only manufacture and distribute multi-line lubrication systems: we advise and accompany We support our customers throughout the selection, installation and commissioning process. We know that each company is unique, so we offer a technical and consultative approach that allows us to recommend the most appropriate system based on the machinery, working conditions and maintenance objectives.

Our specialised engineers carry out a detailed analysis of the equipment to be lubricated, The parameters evaluated include accessibility to critical points, the type of lubricant required, the frequency of operation and the desired degree of automation. Based on this evaluation, a technical proposal is designed with clear specifications, designed to maximise efficiency and minimise downtime.

Installing a RIVI multi-line lubrication system means relying on proven technology, backed by a brand with decades of industry experience. Our systems are designed to integrate without friction in complex production environments and to respond with stability to variations in load, temperature or pressure.

In addition, we offer services from technical support, training for operators, and consultancy to ensure that each system operates at maximum capacity. Our goal is not just to sell you a solution, but to become your strategic partner in optimising your plant's lubrication processes.

Every multi-line system that RIVI installs represents a commitment to the business continuity, We are committed to delivering the highest level of technical reliability and improved profitability in the medium and long term. We invite you to discover how our solutions can transform maintenance management in your company.

Visit our range of lubrication systems and contact usOur specialists will guide you to the most efficient and secure option for your production environment.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions about multi-line lubrication systems

Choosing a multi-line lubrication system is a strategic decision for industrial operations. We know that technical and operational questions arise when considering its implementation. At RIVI, we are committed to providing not only advanced technology, but also the information you need to make informed decisions. Below, we answer the following questions frequently asked questions that we receive from our industrial customers.

How to monitor multi-line lubrication circuits?

By means of pressure sensors, flow detectors and control units connected to PLC or SCADA systems. RIVI offers full integration with industrial monitoring systems.

What are the advantages of choosing a multi-line lubrication system?

Allows precise lubrication and reliable per point in the absence of any intermediate element. It accepts complex fats and oils, even with solids in suspension.

Can I order customised multi-line systems for specific applications?

Yes, RIVI designs tailor-made systems adapted to each type of machinery, operating environment and specific technical need.

Do you provide training on the use of multi-line systems?

Yes, we provide technical training for operators and maintenance personnel to ensure correct and efficient use of the system.

What kind of reliability do multi-line lubrication systems offer?

Esthe systems offer high reliability as there are no elements mechanics intermediate equipment that may fail or break down. Lubricant goes straight from the pump to the points of consumption.