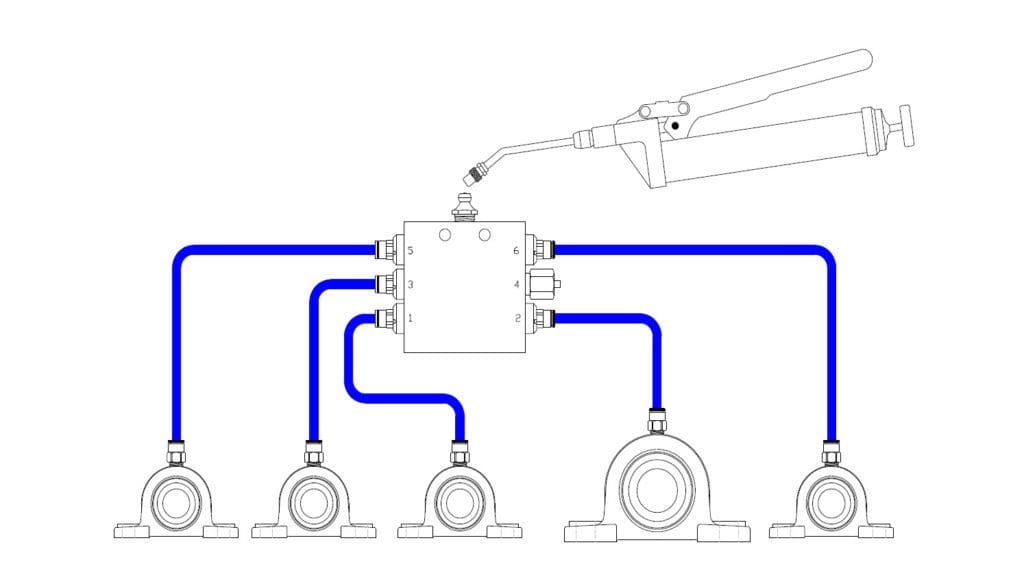

The manual lubrication equipment, also known as point-to-point lubrication, are common in many industrial processes. There is certain situations where manual greasing is still the option of choice: components that are difficult to access, single grease points, auxiliary lines or machinery in locations with no fixed infrastructure.

RIVI has the right tools to to run the lubrication manually in a controlled manner.

Our teams are present in sectors such as automotive, agriculture, mining, construction, food or power generation. Each tool is designed to delivering real value to those who operate in the day-to-day running of plants, workshops or production lines. We design solutions that prevent breakdowns, improve efficiency and optimise your maintenance processes.

On the other hand, in RIVI we recommend automatic systems whenever possible, The new system will help to improve the efficiency and optimisation of lubrication equipment.

Types of manual lubrication equipment at RIVI

At RIVI we offer a range of lubrication equipment and systems that responds precisely to the most specific and demanding manual operational needs. Although they all fulfil the main function of manually applying lubricant, each type of equipment responds to specific situations and different technical profiles. Below, we explain the most relevant ones, all available through our technical-commercial service.

- Lever-operated hand pump: Ideal for applying high-density greases at points requiring high pressure. Their main advantage lies in the precise and clean dosing of the lubricant. Some of these grease nipples are equipped with double-acting mechanisms that allow them to work with minimum operator fatigue. They are used on heavy machinery, industrial vehicles and hydraulic components, and for oil lubrication they are used on gearboxes, chain systems or moving components requiring liquid lubrication. Their nozzles allow for precise reach into narrow areas and these pumps prevent drip losses.

- Electric grease gun: Ideal for repetitive operations and for points requiring constant flow and/or pressure when working with NLGI 0-2 consistency greases. Their main advantage is the uniform and controlled delivery of lubricant by means of a geared electric motor driving a positive displacement pump, which improves accuracy and reduces operator fatigue. Many models incorporate a two-speed selector or variable speed trigger to alternate between high flow and high pressure for restrictive points. Dispensing is clean and repeatable, suitable for preventive maintenance plans with multiple grease fittings. They are used in heavy machinery, construction equipment, transport fleets, agriculture, energy and general industry. They are not used for oil lubrication; specific drip or drip lubrication systems are used for that purpose. circulation.

- Technical accessories: Each system can be supplemented with flexible hoses, safety valves, angled nozzles, additional tanks or quick adapters. These elements increase the operational capacity of each equipment, allowing the user to adapt it to different types of machinery, environments or lubricants. We also offer complete lubrication kits, ready for immediate use, with all the necessary components for professional intervention.

In addition to these product families, at RIVI we provide personalised technical advice to identify which equipment best fits your operational reality. Working on an automated production line is not the same as working in a mobile maintenance plant. Therefore, we analyse the type of machinery, lubrication cycles, environmental conditions and the nature of the lubricant before making a recommendation.

At RIVI, we understand that acquiring lubrication tools is not a simple transaction, but rather a strategic decision with a direct impact on the productivity, safety and profitability of your industrial operation. That's why we've designed a shopping experience that goes beyond product offerings to provide complete technical solutions, backed by knowledge, support and commitment.

Some of the competitive advantages The best ways to buy our manual lubrication systems are:

- Industrial quality assurance: Every piece of equipment that leaves our facilities has been designed, tested and certified to perform in real working conditions. We do not work with generic solutions or improvised adaptations.

- Compatibility with industry lubricants: Our equipment is compatible with industrial greases (NLGI 0 to 3) and low to medium viscosity oils. We assess technical compatibility to ensure that there are no application failures or clogging problems.

- Personalised technical support: You don't buy blindly. We accompany you from the identification of the problem to the choice and use of the most suitable system. Our team of engineers advises you straightforwardly and with clear technical criteria.

- Availability and adaptation: We offer efficient delivery times, configurable options, reinforced versions and customised kits. Our logistics infrastructure is designed to get you what you need, when you need it.

We know that industrial maintenance can't go wrong and that the wrong choice of lubrication tools can cost far more than the product itself. That's why, in every commercial operation we offer something more: a technical vision, field experience and real commitment to results.

Buying at RIVI is to ensure that your investment is aligned with your productivity, efficiency and reliability mechanics. It is to bet on a company that speaks your language, that knows the challenges of the sector and knows how to solve them.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions about manual lubrication systems

The use of manual greasing systems generates a series of technical doubts that it is important to resolve before their implementation. At RIVI, we accompany our customers at every stage of the process, offering clear and professional answers that allow them to make informed decisions. Below, we provide answers to the following questions most common queries related to such solutions.

When is manual lubrication sufficient?

When lubrication points are accessible, lubrication is not continuous and can be controlled manually without compromising operation.

Can I use manual lubrication systems in high temperature environments?

Yes, provided the tool is made of heat-resistant materials and a suitable high-temperature lubricant is used.

How does a hand grease pump work?

It works by manually generated pressure, which propels the lubricant from the reservoir to the point of application through a nozzle.

What manual lubrication tools does RIVI offer?

We offer HAND PUMPS lever, electric grease gunss and compatible accessories.

What are the advantages and disadvantages of manual lubrication?

It allows full control and is cost effective, although it is operator dependent and time consuming if there are multiple grease points. Again, at RIVI we recommend automatic systems whenever possible.