Lubrication systems for special applications

RIVI » Lubrication systems » Lubrication systems for special applications

At RIVI we develop lubrication solutions specifically designed to solve the most demanding challenges of modern industry. We know that not all applications can be addressed with standard solutions. That's why our lubrication systems for special applications are designed to precisely adapt to extreme environments, complex movements and very specific technical requirements.

Each system we design combines innovation, reliability and efficiency operational. Our commitment is not just to offer a product, but to ensure that every customer improves their productivity, reduces their maintenance costs and protects their critical machinery.

Open gear lubrication system

Lubrication by primer pinion

Our system of primer pinion applies the grease directly onto the gear teeth by means of a synchronised mechanism.

This method ensures a constant and uniform lubricant film during movement, reducing friction, heating and the risk of mechanical failure.

Unlike manual methods or drip system, this system works in the following way automated, efficient and safe. It is the ideal solution for rotary kilns, mills or large rotary equipment with low to moderate speeds (exclusively for the cement industry).

Implementing this technology is a strategic decision that directly impacts the reliability and continuity of your operation.

Lubrication system for chain conveyors

In intensive production lines, the chain conveyors are essential elements. Their correct lubrication has a direct impact on the overall performance of the system. RIVI designs lubrication systems that act precisely on each link and roller, minimising wear and ensuring uninterrupted operation.

Chain Conveyor Lubrication: Cobra/GVP

The system Cobra/GVP has been developed to apply lubricant exactly where it is needed, on the move and without the need to stop the conveyor. It is an automated solution, adaptable to multiple configurations and capable of working in harsh environments., The company is also active in the automotive industry (paint booths) and the steel industry. Thanks to the Cobra/GVP technology, it is possible to greasing chain conveyors in operation, prevent premature breakages and reduce downtime.Moreover, integration into existing lines is fast and safe, allowing immediate results without compromising production.

Manual lubrication and tank refilling system for wind turbines

Efficiency in WIND FARMS not only depends on the performance of the generator, but also on operational continuity without unforeseen maintenance. RIVI provides safe and professional solutions for lubrication of wind turbine components, and the refilling of tanks of lubricants at heights or in areas that are difficult to access.

Hyflow and TLeS (Transfer and lubrication electric system) fast filling systems

Our systems Hyflow and TLeS allow the filling of lubricant reservoirs in wind turbine nacelles in a fast, safe and controlled manner.

They are designed to facilitate the operator's work, The use of the product in the process reduces risks and avoids contamination during the process.

Both devices are designed for demanding environments and are perfectly suited to technical protocols in the energy sector.

Choosing these solutions means protecting the performance of your wind farm and significantly reducing maintenance-related incidents.

Wire ropes and cables are vital components in sectors such as the mining, logistics, naval or elevation. Their service life depends to a large extent on thorough and constant lubrication., as they tend to work in extreme environmental conditions.. At RIVI we design systems that fully lubricated the cable for all-round protection.

WRL for cable lubrication

He WRL system allows cables to be lubricated while in operation, without stopping the machinery. Through an enveloping head, the lubricant is applied evenly, displacing moisture, dirt and preventing internal oxidation.

This solution is key for continuous operations where shutting down equipment is costly. It is mainly used in vessels, harbour cranes, and other machinery subject to corrosion. With WRL, you increase operational safety, reduce faults and extend the service life of cables without interrupting your production.

Air-oil lubrication system

When it comes to high speed or precision mechanisms, conventional lubrication may not be sufficient. At RIVI we offer air-oil systems that guarantee constant protection without generating waste or excess.

Air-oil technologies

Our systems mix a micro-dosage of oil with compressed air, This generates a thin lubricating film that is transported to the exact point of application.

With this technology, air is used to transporting the oil to the consumption points. This method is perfect for spindles, high-speed bearings and contamination-sensitive components.

This technology can be apply in:

Implement air-oil technology in your processes means increasing technical reliability, optimising lubricant consumption and reducing wear on key components.

MQL - Micro oil spraying system

This is a very widespread application, where the lubricant used is generally taladrine or other emulsions similar. The purpose is to cool the mechanisms used for the treatment, machining and/or processing of metals, generally referred to as “machine tools”.

The system consists of adding the fluid (water + oil, or similar) at frequent intervals or even continuously, synchronising this dosing with compressed air so that it covers the required surface area. In this case, in addition to lubricating, the aim is to cool.

The oil is transported through a normally flexible pipe, inserted in another pipe of larger diameter (externally concentric), through which it is transported. transports compressed air. This pipe is called “coaxial”. Air and oil are mixed at the outlet, resulting in spraying.

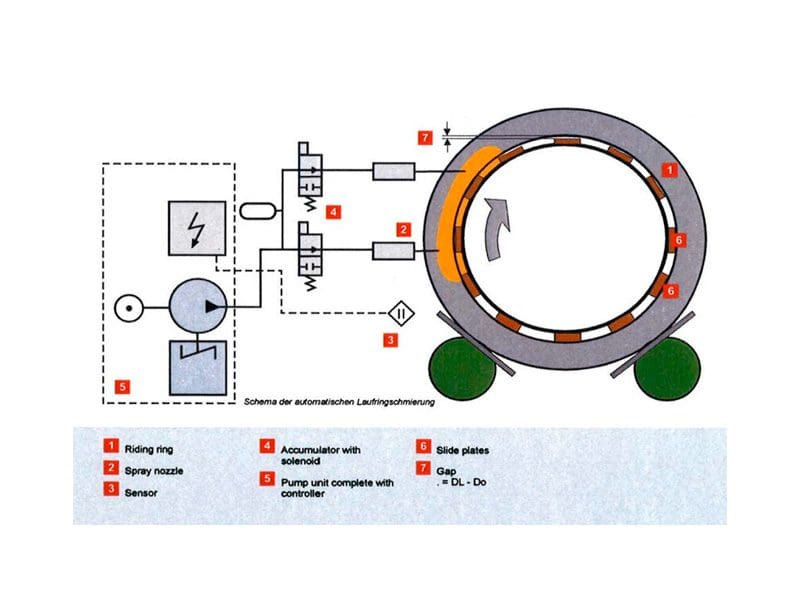

Kilnjet system for treads (kilns and rotary mills)

The conveyor belts in rotary kilns and rotary mills (usually in cement factories) are subjected to high loads, extreme temperatures and constant movement. Our Kilnjet system has been specifically designed to cope effectively with this hostile environment.

Kilnjet applies lubricant to the lubrication points, ensuring a complete coverage without the need to stop the machine (kiln or mill). This results in less wear, better load distribution and a significant reduction in maintenance costs.

It is the professional solution that your plant needs to ensure operational continuity in critical equipment.

Stationary track lubrication systems

In the railway sector, The friction between the wheel and the rail represents a constant technical challenge. Our stationary rail lubrication systems - also known as rail lubricators or rail lubricators - ensure precise and sustainable lubrication at key points in the rail infrastructure.

Choose both our RAAS and RLS systems is to improve efficiency without sacrificing environmental commitment, as they are compatible with friction modifiers and biodegradable greases, and ensure continuous intervention without the need for frequent maintenance. These rail lubricators are essential for preserving rail infrastructure and improving operational performance.

Currently, our stationary systems are technologically the most advanced in the world.

Track lubrication with RLS (railroad lubrication system)

He RLS system apply the lubricant directly to contact areas between the rail and the wheel, especially in curves. This reduces friction between the wheel flange and the track sidewall, prolonging the service life of both components.

There are RLS systems embarked (on board the vehicle) and stationary, The latter are much more effective.

Railroad acoustic attenuation system (RAAS)

He RAAS system applies a so-called “friction modifier” fluid to the tread. This prevents so-called ”undulatory wear” and its consequences (such as squealing when cornering).

There are RAAS systems embarked (on board the vehicle) and stationary, The latter are much more effective.

On-board wheel flange lubrication systems

RIVI offers embedded systems which are integrated directly into the rail vehicle to lubricate the wheel flange according to its position and dynamics. This reduces the wear of the wheel-rail assembly and minimises energy consumption, prolongs the service life of track and wheels, as well as the intervals between maintenance.

They are systems intelligent, programmable and adaptable to passenger trains, trams, metros, freight locomotives, trainsets, railway trucks etc.

They represent a technical investment with direct return in performance, durability, comfort and energy efficiency.

Lubrication of railway electrification catenary (Coplaluber)

The catenary is an essential element in railway electrification, and its wear and tear compromises the stability of the service. At RIVI we develop Coplaluber, a system that precisely and automatically lubricates the contact wire to prevent excessive friction and damage to the pantograph. (available in electric version for autonomous vehicles without active catenary).

As with on-board systems, the catenary lubrication systems are also intelligent, programmable and adaptable to all types of rail vehicles.

Prevention of ice cuffing

Coplaluber avoid, during the cold months, the formation of ice on the catenary of railway electrification, The solution guarantees a clean and stable electrical contact. This solution improves safety, reduces incidents and ensures operational continuity, even in adverse weather conditions.

The lubrication system for your special application from RIVI

Every industry, every process, every component has different needs. At RIVI, we do not offer generic products: we develop tailor-made technical lubrication solutions that integrate, work and make a difference from day one.

With a specialised technical team, proprietary technology and a firm commitment to quality, RIVI helps you protect your investment, increase the efficiency of your processes and reduce the risks associated with industrial maintenance. If you are looking for a durable, accurate solution designed to perform where other systems fail, contact us. RIVI is your reliable partner for advanced technical lubrication.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions about systems for special applications

Se know that technical decision-making requires clear, accurate and experience-based information. That is why we respond to the frequently asked questions about our lubrication systems for special applications, aimed at industrial sectors that require specific, reliable solutions with a direct impact on operations.

What are lubrication systems for special applications?

They are tailor-made lubrication solutions for industrial environments where working conditions require more advanced technologies than conventional systems., or solutions not yet developed at the present time. At RIVI we develop these systems to maximise efficiency, protect critical assets and precisely match each application.

What are the advantages of using customised lubrication systems?

They allow precise control over the point, quantity and frequency of lubrication, reducing wear and tear, failures, operational costs and, above all, adapted to the conditions prevailing in each particular project. Choosing a RIVI customised system means investing in reliability, performance and durability for your plant.

Can a conventional lubrication system be upgraded to a special application lubrication system?

Normally sí, although each case needs to be studied on a case-by-case basis. At RIVI, we offer a professional engineering service to define the most optimised solution at the lowest cost for each client..

Are specialised personnel required to install lubrication systems in special applications?

Our technical team will can commissionsr installation and start-up. In addition, we train your staff so that they can operate the system with complete autonomy, reducing dependence on our external support.

How do I know if I need a special or standard lubrication system?

If your operation is carried out in demanding conditions, with critical machinery or processes that do not tolerate interruptions, you need an advanced solution. At RIVI we analyse your environment and advise you with technical rigour so that you invest only in what you really need.