At RIVI, we specialise in advanced solutions for rapid drop lubrication for chain lubrication, The new, high-performance technology allows precise and consistent application of the lubricant to the chain links.

Our systems are designed to integrate easily into demanding industrial environments, ensuring the right supply of lubricant without excesses, without losses and with the control that industry needs. At sectors such as food, automotive, logistics or series production, the rapid drop lubrication optimises operational performance, protects moving components and significantly reduces maintenance costs.

Choosing RIVI is to bet on a reliable technology, designed with technical rigour and built to last.

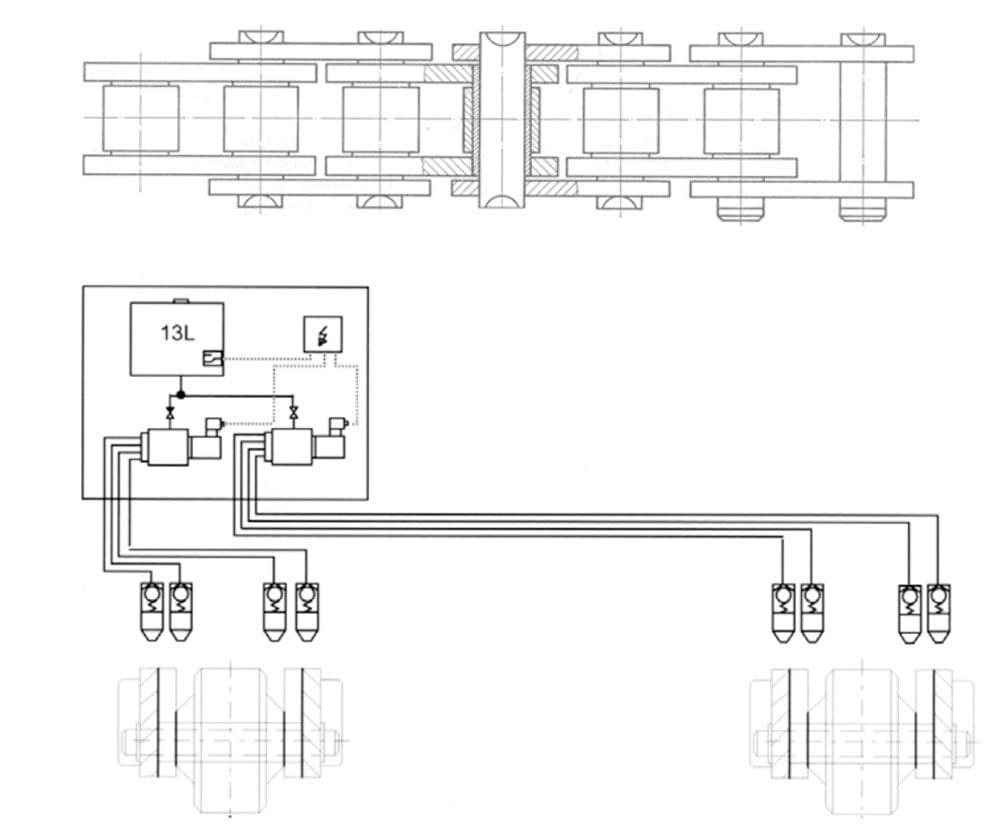

Rapid drop lubrication system for chains

Chains are critical elements in many industrial processes. Correct lubrication not only ensures smooth movement, but also prevents breakages and breakdowns that can bring production to a standstill. At RIVI, we have perfected rapid drop lubrication systems for chains, The new system offers a solution that is perfectly adapted to automated production lines or continuous working equipment.

This system allows an exact dosing of the lubricant, directly on the links and friction zones. The application is precise and clean, without spillage, and can be regulated in intensity and frequency. This ensures that the chain always operates with the lowest possible coefficient of friction, reducing wear and maintenance downtime.

Our systems work by electromagnetic pumps with fixed flow rate (30 or 60 mm³ per outlet) which, activated by a detector signal, accurately dispense the lubricant. Each nozzle incorporates calibrated non-return valves, ensuring simultaneous, clean and leak-free dispensing. This technology guarantees the exact amount of lubricant at the right pressure for each cycle.

Among its main technical advantages we highlight:

- Precision at every drop, preventing excessive dripping and reducing the need for cleaning.

- Increased durability of components by minimising metal contact abrasion.

- Improved energy efficiency, thanks to smoother operation of the mechanical system.

Implementing this solution in your machinery allows you to save on repair costs, avoid unscheduled downtime and keep the pace of work stable and safe. thanks to the fast drop.

Rapid drop lubrication for slides and conveyors

Guides and conveyors are key parts in production and logistics systems. If their movement is affected by poor lubrication, the consequences can be costly. The rapid drop lubrication by RIVI offers an advanced and effective alternative to maintain the good condition of these components without the need for constant intervention.

Our system applies the lubricant precisely, only at the points where it is really needed, eliminating risks of over-lubrication. Thanks to its robust engineering and adaptable design, it can be installed on all types of conveyors, from simple belts to complex industrial automation.

This type of solution significantly improves the smoothness of displacement, reduces operational noise and lowers energy consumption. In addition, the regular supply of oil avoid blockages or jumps that may alter the production process.

The result is a more reliable, silent and durable installation. RIVI offers you a technical system that works in favour of your operational profitability.

Industrial reality is diverse, and at RIVI we understand this perfectly. That is why we offer fully customised quick-drop lubrication systems, designed to meet the exact technical requirements of each machine and each process.

Our proposal goes far beyond a standard product. We study your case comprehensively, identify the critical lubrication points and develop a tailor-made solution that integrates perfectly with the structure and operation of your machinery. This customised approach guarantees:

- Full compatibility with your operating environment.

- Optimisation of lubricant consumption.

- Reduction of technical downtime.

The process of design and implementation is carried out by an experienced technical team, which oversees everything from initial analysis to final commissioning. This ensures a smooth and efficient installation with immediate results in terms of performance and durability.

With the RIVI customised systems, lubrication is no longer a risk factor but a competitive advantage.

Order your Rapid Drop Lubrication System at RIVI

If you are looking for a solution that optimises the maintenance of your machinery, eliminates downtime and protects the chains or guides of your machinery, you are in the right place. At RIVI, we help you to make the leap to a lubrication system. modern, controlled and efficient.

Through our technical advice, we identify the best solution for your plant or workshop. We design, manufacture and install fast-drop systems that meet the highest industry standards, both technically and operationally.

Our experience, combined with a clear focus on the industrial customer, makes us the ideal partner for protecting your investment and ensure the continuity of your production.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions on Rapid Drop Lubrication

The decision to implement a quick-drop lubrication system is not only a technical improvement, but also a strategic commitment to operational reliability. For this reason, we solve your doubts with clear answers that will help you make an informed decision aligned with your company's objectives.

In which cases are quick-drop lubrication systems used?

They are mainly used in machinery with continuous motion and specific friction points, such as chains, guides and conveyors. If your equipment requires precise lubrication without stopping production, this solution is ideal for you.

What are the benefits of rapid drop lubrication in industry?

Ensures precision and cleanliness in lubricant application. If you are looking to improve these aspects in your production line, this technology is key to achieving this.

Does the Rapid Drop Lubrication System require regular maintenance?

Yes, but it is minimal. All that is needed is fill in on deposit of lubricant and check the general functioning of the system. If you want to keep your equipment in top condition without complications, this is an excellent choice.

Is a quick-drop lubrication system reliable?

Absolutely. Its operation is stable, precise and adaptable to different working conditions. If you need a continuous and uninterrupted lubrication solution, this system is your best ally.

Do you offer installation and maintenance services for fast-drop systems?

Yes, at RIVI we take care of the entire process: from services from design to installation and subsequent technical support. If you want to guarantee optimum operation from day one, contact our specialised team.