In industrial environments where precision and operational reliability are imperative, the dual line lubrication systems are positioned as the ultimate solution to ensure the continuous operation of machinery. At RIVI, For decades, we have been designing and implementing systems that meet the highest technical and performance standards.

This type of system is intended for industrial plants that require the lubrication of numerous critical points automatically, safely and programmed. This prevents premature component wear, reduces unplanned downtime and improves the overall efficiency of the production process.

At RIVI, we don't just supply technology: we provide a sustainable competitive advantage for your business.

Dual line lubrication equipment

The quality and reliability of a greasing system depends directly on the type of equipment used. At RIVI, we work with advanced engineering solutions to provide dual line lubrication equipment designed to withstand the most extreme working conditions, from dusty or humid environments, to high temperatures or the presence of contaminants.

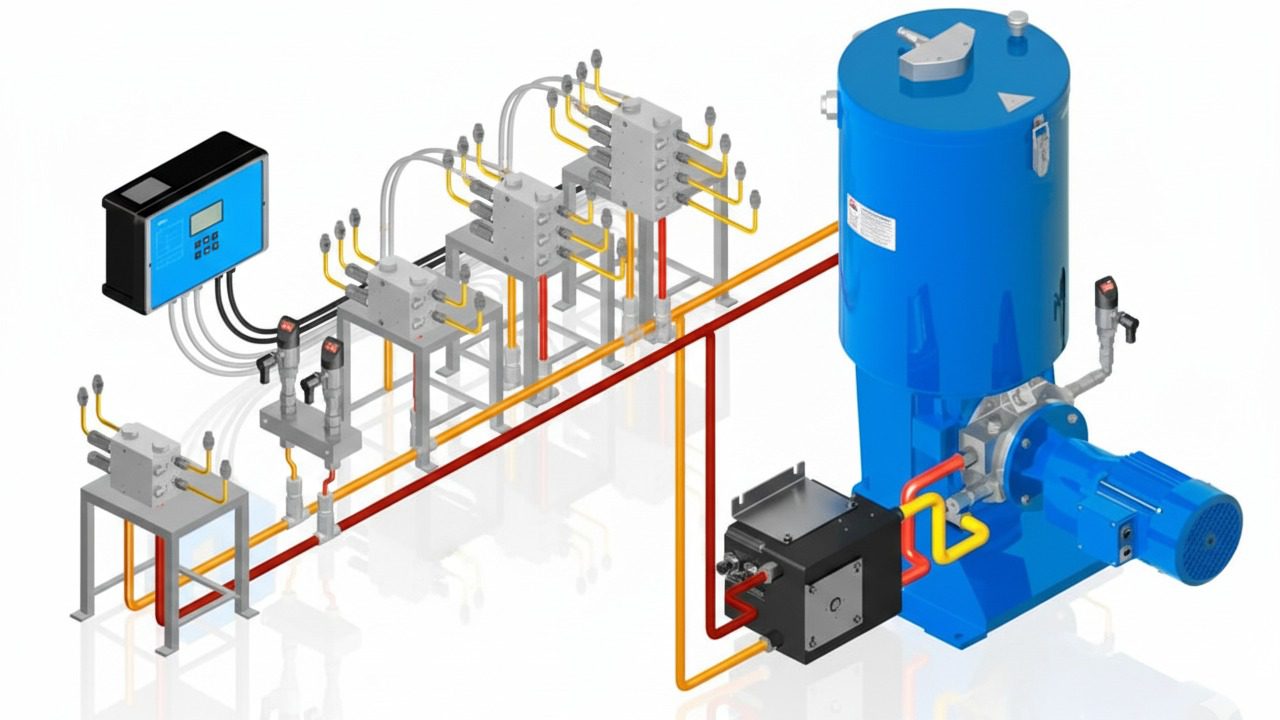

Our equipment includes:

- High pressure pumps, The lubricant is distributed over long distances with total precision.

- Volumetric distributors that ensure exact dosing at every friction point.

- Control and monitoring units, These allow real-time monitoring of the system's performance and anticipate possible incidents.

Thanks to this modular and scalable architecture, our systems are perfectly adapted to sectors such as mining, energy, cement, automotive, paper and steel. Most importantly, they ensure consistent lubrication with no margin for error, extending the life of your equipment and optimising the return on your industrial investment.

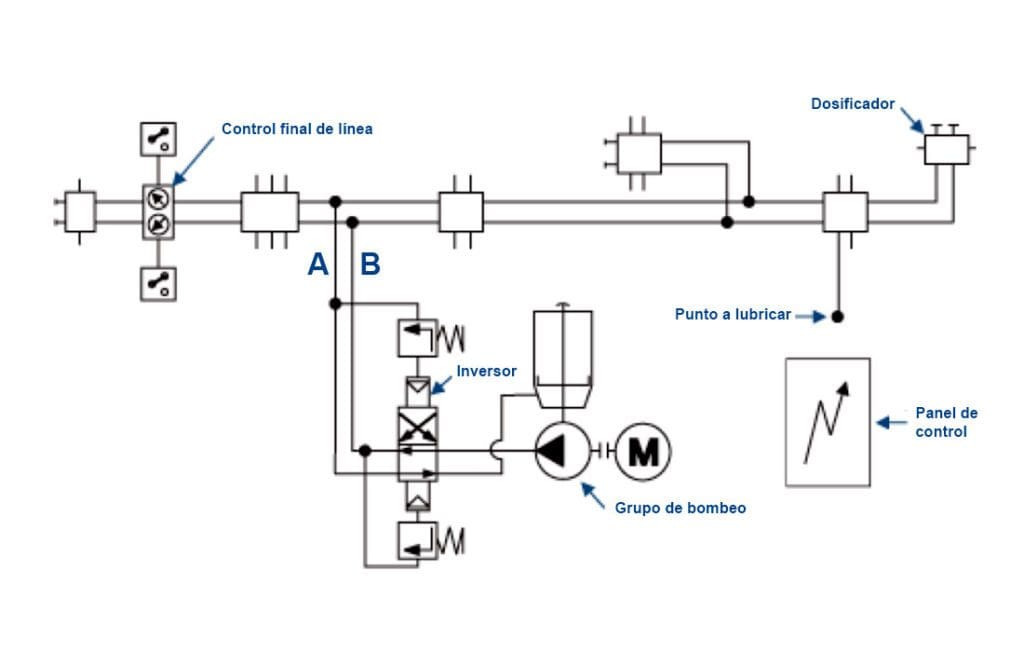

This is because the operation of the dual line system is based on a principle of alternating pressurisation. During the first half of the cycle, the pump pushes the lubricant through line A, while line B remains unloaded. Once the lubricant has been distributed to the consumption points, the pressure in line A is raised to the value set by the controller.

The system then reverses the flow: line A is depressurised and line B is pressurised, repeating the same process. This hydraulic alternation ensures that all points receive the exact amount of lubricant and enables reliable distribution even in large installations or under severe conditions.

The types of dual line lubrication that we offer

At RIVI we understand that each installation is unique. For this reason, we offer various types of dual-line systems, The range of products is tailored to the specific needs of your machinery, operating volume and working conditions.

Our systems include:

- Grease lubricationIdeal for high friction equipment and heavy duty environments.

- Oil lubricationDesigned for mechanisms that require fluidity, heat dissipation or continuous cleaning.

- Electrical and pneumatic systemsDepending on the type of automation and the infrastructure of your plant.

- Centralised or sectorised distributionAdapted to the structural complexity of the equipment or process.

Each of our systems is designed to integrate seamlessly into your existing operations, without the need for plant redesign. In addition, our engineers perform a detailed technical analysis to identify the exact type of lubrication best suited to each point of installation.

Our Smart Dual Line System (S-DLS)

At RIVI we have developed the Smart Dual Line System (S-DLS), S-DLS, an intelligent dual-line lubrication system that takes performance to a new level. The S-DLS is the result of years of innovation applied to the field of industrial lubrication and represents a natural evolution towards full automation of preventive maintenance.

Among its advantages stand out:

- Real-time technical diagnostics, The system is equipped with strategically positioned pressure and flow sensors.

- Programmable electronic control, which regulates lubrication cycles according to the actual demand of the system.

- Remote monitoring, S-DLS can be integrated into SCADA platforms or other industrial monitoring environments.

- Reduction of lubricant consumption, by means of precise point-to-point dosing.

- High level of customisation, The number of outlets and types of lubricant compatible.

- Fully hydraulic operation, without internal springs that can become fatigued with use.

- Possibility to regulate the flow rate The lubrication system is designed to provide a high level of downstream lubrication even after installation.

- Visual or electrical monitoring at each pair of outlets of the dispensers.

- Fault toleranceIf an outlet or bearing is jammed, the rest of the system continues to operate normally.

- Unlimited number of points, easily expandable without redesigning the entire installation.

This system has been specially designed for companies that are looking for reduce manual intervention, avoid overgreasing and minimise mechanical failures due to wear and tear, improving the control of lubrication in the various systems. Its flexible configuration allows a progressive implementation without stopping the activity of the plant..

Investing in RIVI's S-DLS means adopting an industrial 4.0 approach to lubrication: smarter, safer and more cost-effective.

At RIVI we believe that a precise installation and a maintenance are essential to ensure the performance of any dual-line lubrication system. That's why we not only provide high-quality equipment, but also ensure that each system is fully adapted to the actual plant conditions.

Our engineers thoroughly evaluate each installation, designing solutions that optimise the lubricant distribution and operational efficiency. Installation is carried out by specialised technicians, ensuring safe and seamless integration into production.

After start-up, we offer a continuous technical support. We do services We monitor the condition of the system and take preventive action to avoid failures. In this way, our customers can rely on a system that maintains its performance over time, with the peace of mind of having the technical support of an expert team.

Request a quote for your dual line lubrication equipment

We know that every minute of production counts and that every mechanical failure represents a direct loss. That is why, at RIVI helps you to transforming your maintenance into an operational advantage, offering you the most advanced solutions on the market.

Request a quote is the first step to increasing the reliability of your processes and extending the life of your industrial assets. Our technical team will assess your specific needs and design a system that is fully adapted to your operation, without complications or standard solutions.

We invite you to get in touch with us through our website, where one of our technical advisors will respond with the most suitable solution for your plant, your production targets and your level of automation.

Don't postpone any longer the decision to protect your machinery. At RIVI we offer you systems and equipment that make a difference.

- 360º service: design, installation and maintenance

- In-house engineering, design and manufacturing

- More than 30 years of experience

- Benefits

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

- Contact Us

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

Since we started using RIVI Technical Group's lubrication systems and fluid technology, things have changed quite a bit. The machines run much more smoothly and we have had far fewer surprises with unexpected stoppages.

David Ruiz

Maintenance Technician

Questions on dual line lubrication

At RIVI, we know that investment in lubrication technology must be backed by technical clarity and total confidence in the implemented solution. That's why we answer some of the questions below. frequently asked questions about our dual-line systems.

What is the difference between dual-line and single-line systems?

The dual line system alternates the flow between two lines, while el of single line uses a single line and stops during each greasing cycle.

What are the benefits of choosing a RIVI intelligent dual line system?

Enables real-time control, reduces lubricant consumption and integrates with digital systems. Improves efficiency and minimises manual interventions.

Can the amount of lubricant supplied in a dual line system be adjusted?

Yes, it is possible to configure the dosing at each point according to the needs of the equipment.

Is a dual line lubrication system suitable for high precision machines?

Yes, its precise and constant dosing protects sensitive components without impairing their function.

Can I integrate dual-line lubrication systems with other automated systems?

Yes, our systems are compatible with PLCs and SCADA platforms for centralised and automated control.