Lubrication Systems

At RIVI, we have spent decades leading the development and implementation of industrial lubrication systems, manufacture of tanks and fluid skids adapted to the needs of each customer.

Our expertise not only ensures maximum performance of your equipment, but also translates into real savings in the medium and long term. We know that a lubrication system is not an expense, but a strategic investment for industrial growth.

Proper lubrication prevents unexpected downtime, reduces wear, and maximizes the lifespan of every component. At RIVI Technical Group, we help you understand the importance of each system so you can make an informed and confident decision when purchasing the most suitable lubrication system. Discover everything we offer!

Grupo Técnico RIVI offers a complete 360º service to cover all the needs that the customer may have.

Intelligent solutions that minimise breakdowns and ensure continuous operation of machinery.

From installation to supervision, we offer a 360º service so that you don't have to worry about anything.

Mist Lubrication

Used in pneumatic tools, high speed gears and continuous motion machinery.

The mist lubrication RIVI offers a clean, efficient and extremely effective alternative in environments where other systems fail or are not as suitable.

Circulation and Recirculation System

This system keeps the lubricants in constant motion, ensuring cleanliness, cooling and oxygenation.

At RIVI we integrate it especially in turbines, compressors and high-power hydraulic systems, The system allows total control of temperature, viscosity and purity of the lubricant or fluid.

Traditional Lubrication Systems

Despite technological progress, the traditional lubrication systems are still a valid option in many applications. At RIVI we offer them fully optimised, incorporating high quality materials and configurations adapted to different sectors.

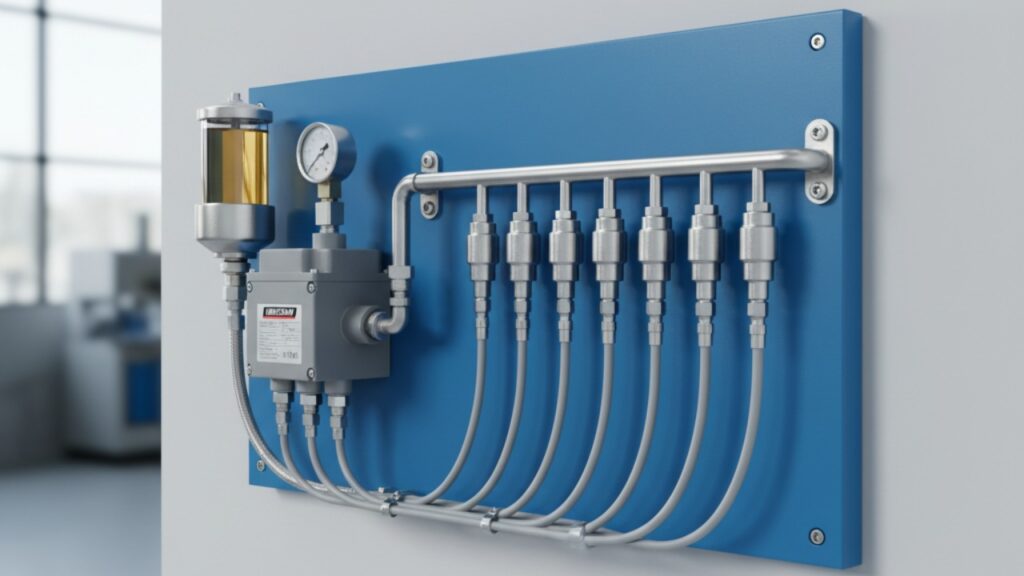

Our range includes manual, single-point, centralised and automatic solutions that ensure reliable lubricant application in every operating cycle.

Read more about the system

The single point lubrication systems are designed to provide a precise, self-contained and cost-effective solution for specific points of difficult access or high criticality. Thanks to their compact design and continuous dosing, they reduce the risk of over-lubrication and ensure constant equipment protection.

Our systems are supplied with cartridge oilers and adjustable timers, which allows our customers to forget about daily maintenance without sacrificing efficiency.

Read more about the system

At RIVI we understand that there are applications where manual intervention is still necessary. For this reason, we offer manual lubrication equipment robust, ergonomic and highly durable, perfect for processes requiring visual inspection or direct control.

We supply lever grease nipples, equipment and portable kits for small and medium-sized installations. In addition, we offer technical advice to train personnel in the correct application of lubricants, avoiding common mistakes that can lead to costly repairs. On the other hand, at RIVI we recommend automatic lubrication systems whenever possible.

Read more about the system

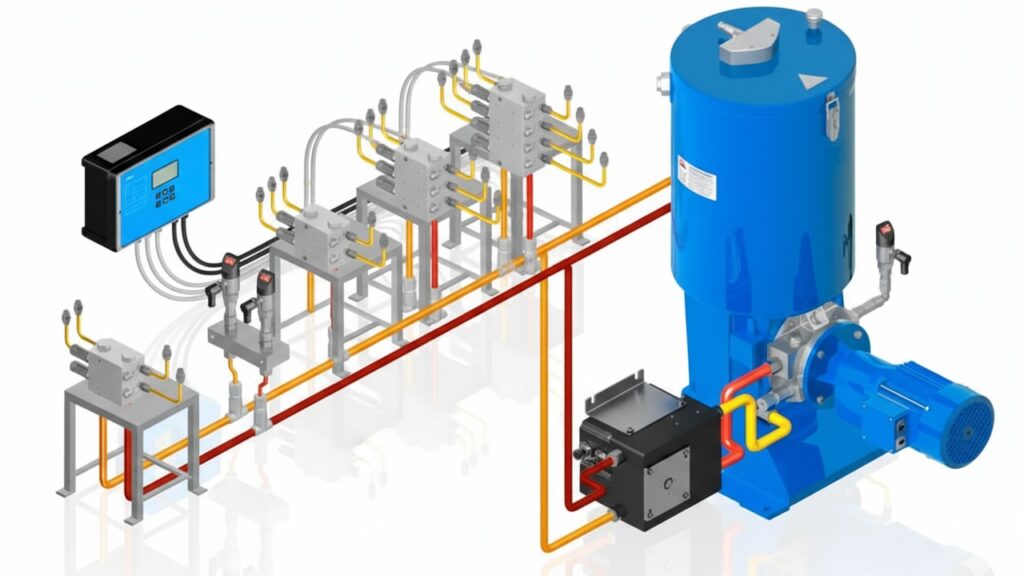

Our multi-line systems are an advanced solution that provides simultaneous lubrication to multiple points independently. Each pump output behaves as a stand-alone system, ensuring precise flow where it is needed most.

This type of system is suitable for heavy machinery, harsh industrial environments and critical applications where no interruption of service can be allowed. At RIVI we customise these systems for production plants, mining machinery and continuous industrial processes, among others.

Read more about the system

The single line is a cost-effective and functional system for the lubrication of up to hundreds of points, thanks to its ability to operate with dispensers in series. At RIVI we develop these systems for companies looking for a first automation with low maintenance costs.

Ideal for agricultural machinery, conveying systems and industrial chains, our single line systems ensure homogeneous distribution of the lubricant, even under adverse ambient conditions.

Read more about the system

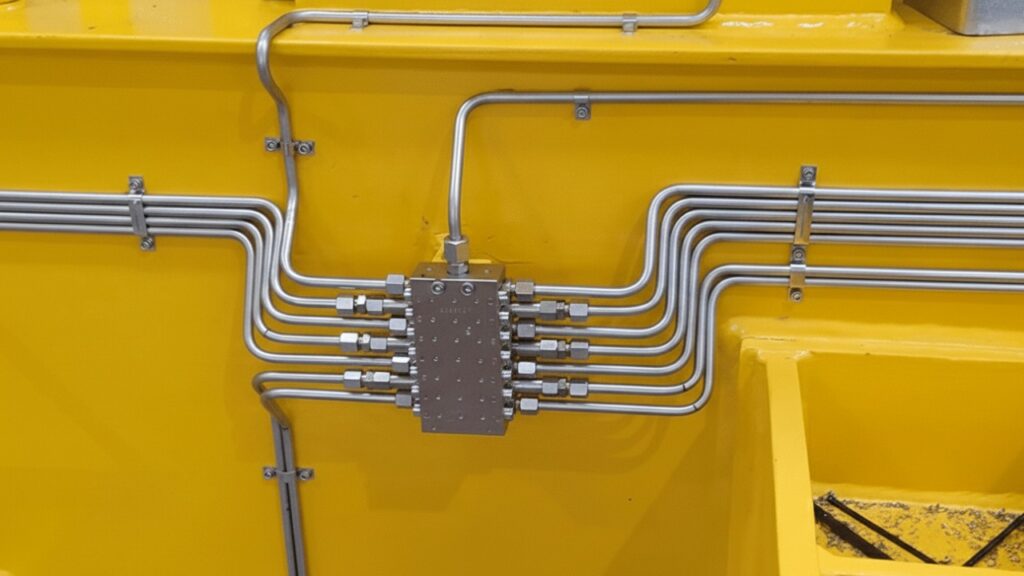

In environments where reliability is everything, such as steel mills or chemical plants, the dual line systems from RIVI are the best choice. Designed to cover long distances and ensure continuity of flow even if a line is compromised, they allow uninterrupted operations.

Our technology ensures total control of cycles, pressure and return, allowing remote monitoring and predictive maintenance. Choosing this system means choosing security, continuity and control.

Read more about the system

The progressive systems RIVI's products are characterised by their millimetre-accurate precision and monitoring capability. By means of sequential distributors, they ensure that each point receives exactly the amount required, and that the system stops working in the event of a blockage or failure.

They are perfect for automated machinery, Our systems include intelligent sensors and digital interfaces, offering a firm step towards Industry 4.0. In addition, our systems include intelligent sensors and digital interfaces, offering a firm step towards Industry 4.0.

Read more about the system

In high-speed operations, such as in the textile industry or paper manufacturing, lubrication must be constant and controlled. Our rapid drop systems deliver micro-quantities of oil at just the right time, minimising waste and maximising efficiency.

At RIVI, we adapt these systems to any type of rotating or fast-moving machinery, The new system will improve performance without the need for major modifications.

Read more about the system

When it comes to the lubrication of large surfaces or exposed areas, our spraying systems are the ideal solution. They use compressed air to project grease in the form of a controlled mist, evenly coating chains, open gears and conveyors.

At RIVI we design these systems for applications in the iron and steel industry, cement plants and large industrial conveyor belts, offering precision, efficiency and savings product.

Read more about the system

We know that every sector has its challenges. That is why at RIVI we develop tailor-made lubrication systems for industries such as food, pharmaceuticals, wind power and shipbuilding, among others, complying with specific cleaning, temperature and pressure regulations.

Our engineers work side by side with your team to deliver a fully customised solution, The new, safe and efficient.

Centralised Lubrication Systems

The centralised RIVI systems fully automate the lubrication of machinery and production lines, improving equipment availability and reducing downtime.

We integrate solutions that include electronic controllers, level sensors and pressure switches, all with IoT connectivity for remote monitoring and reporting. This is the ultimate solution for companies looking for reduce costs and increase operational efficiency.

Lincoln Lubrication System

SKF Lubrication System

Grease Dosing Systems

Fluid Technology Systems and Solutions

Beyond lubrication, RIVI offers advanced solutions in the following areas industrial fluid management, helping to maintain the quality, efficiency and cleanliness of each process.

It offers the possibility of integrating customer-supplied components, both commercial and in-house manufactured. In addition, RIVI performs the following functions audit and maintenance of installations and large fluid circuits, especially lubrication (greases and oils). If you need more information, please ask our technical team about fluid technology systems.

Varnish Removal

The varnish generated by the oxidation of oils can be the enemy of your industrial equipment. At RIVI we implement chemical and physical cleaning technology to eliminate these residues without compromising operation, prolonging the life of lubricants and reducing operating costs.

Pumping and transfer equipment

RIVI offers industrial pumping solutions for the safe transfer of oils, greases, chemicals or coolants. Whether pneumatic, electric or hydraulic pumps, we guarantee constant flow, safety and efficiency.

Degreasing Systems

Our catalogue includes industrial degreasing systems by ultrasound, steam or biodegradable products, ideal for maintenance, manufacturing or pre-assembly processes. Suitable for all types of parts, from bearings to electronic components.

Fluid and Gas Treatment Skids

Our systems for fluid and gas treatment remove particles, water, air and contaminants, ensuring a clean and stable environment for your processes. Available with ISO certifications and connectivity for continuous monitoring.

Questions about our Lubrication Solutions

At RIVI, we know that choosing the right lubrication system is a technical decision, but also a strategic one. That's why we want to provide clear answers to your questions. frequently asked questions that our customers have before they place their trust in us. The same applies to the selection of degreasing equipment, fluid circuits (oxygen, hydrogen...) and tanks.

This section will help you better understand the value we bring to the table and why one hundred andMore companies are already optimising their processes with our solutions.

What is an industrial lubrication system for?

The main purpose of an industrial lubrication system is to protect and optimise performance of the mechanical components of a machine. By reducing wear, minimising friction and controlling temperature, it enables more efficient, safer and longer lasting operation. It also helps to reduce maintenance costs, avoid unplanned downtime and increase the productivity of any plant.

What types of lubrication solutions does RIVI offer?

At RIVI we offer a wide range of solutionsOur products range from traditional manual systems to state-of-the-art automated technologies. Our offerings include single-point lubrication, progressive lubrication, dual-line systems, precision dispensing, grease spraying, mist, recirculation, and customised solutions for special sectors such as food and pharmaceutical. Each system is designed to meet the specific challenges of our customers.

What are the characteristics of RIVI lubrication systems?

RIVI's systems are characterised by their reliability, precision and advanced technology. They incorporate wear-resistant materials, intelligent sensors, digital interfaces and connectivity options that allow real-time monitoring of operation. In addition, all our products comply with stringent industry standards and are designed to integrate quickly into existing production environments.

Does RIVI design customised lubrication systems?

Yes, in RIVI we design tailor-made solutions according to the operating conditions, type of machinery, work cycles and industrial environment of each customer. Our technical team analyses the specific needs and develops a greasing system that maximises performance and minimises risks, adjusting to the budget and technical requirements of each project.

How do I know if I need to upgrade my lubrication equipment?

Some clear signs are: increased lubricant consumption, abnormal noises or vibrations, increased number of mechanical failures or frequent maintenance. It is also advisable to evaluate your systems if your machinery is old, if production has increased or if you are losing energy efficiency. At RIVI we carry out accurate diagnostics to help you identify specific areas for improvement and offer you a realistic and cost-effective proposal. Call us at if you need advice regarding your lubrication equipment or our solutions.

What is an industrial skid and what is it for?

A skid is a modular system that integrates equipment, piping and instrumentation to facilitate the movement of fluids in industrial plants and their use in processes.

What types of skids does RIVI manufacture?

We manufacture skids for pumping, filtration, cooling, heating, dosing and special systems for different processes.

Do you offer on-site installation and commissioning?

Yes, we assist in the assembly, connection, adjustments and final validation of the system on site.

At RIVI Technical Group we design, manufacture and install equipment adapted to each industrial sector. Tell us about your project and we will advise you with the best technical and economic solution.

- More than 30 years of experience

- In-house engineering, design and manufacturing

- 360º service: design, installation and maintenance

RIVI lubrication systems have made our operations much smoother. Thanks to their technology, we have improved efficiency and made our equipment last longer without complications.

Juan Pérez

Production Manager