Lubrication

systems and equipment

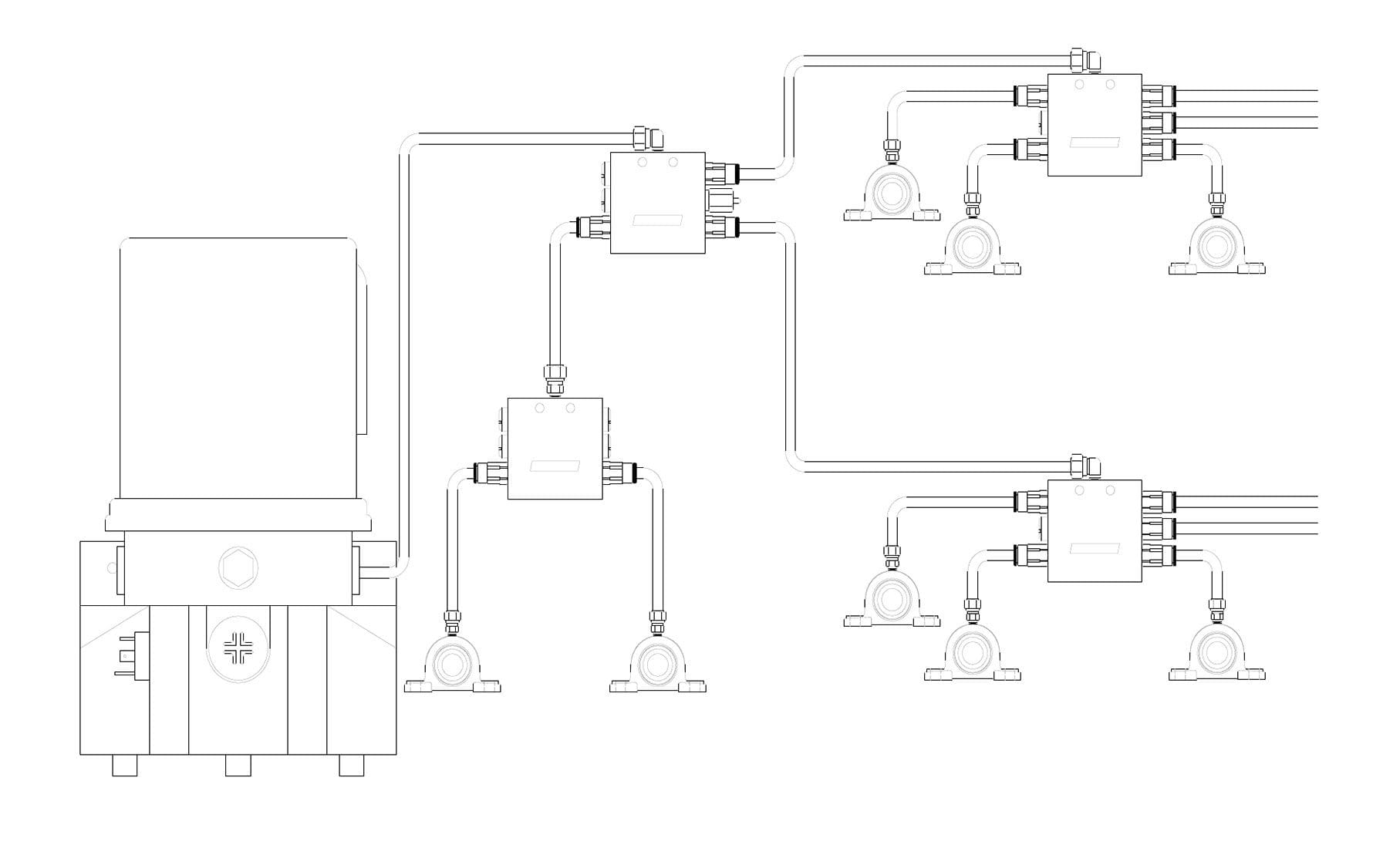

Progressive

The system will continue to operate as long as the pump keeps working. When the pump is turned off the system's grease distributors will stop, and they will resume from the same point when the system is restarted.

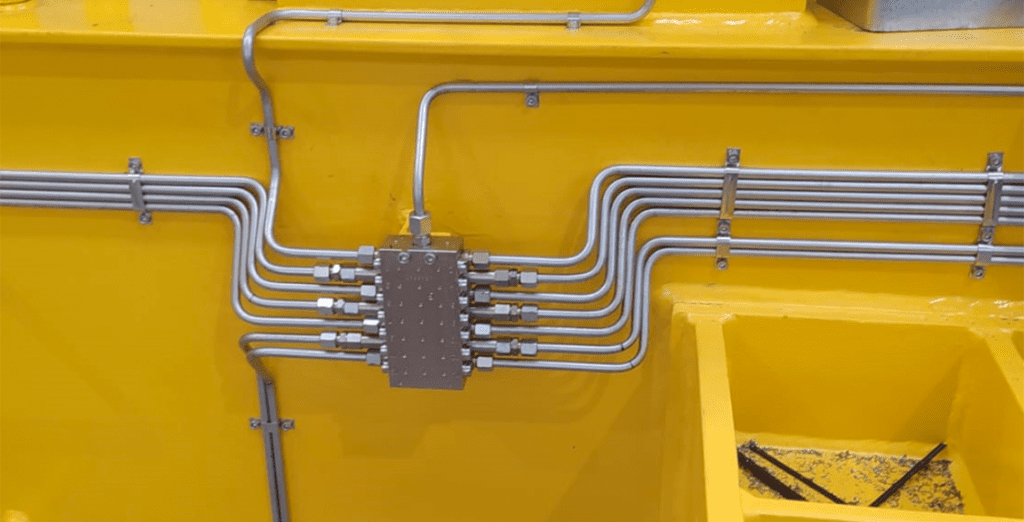

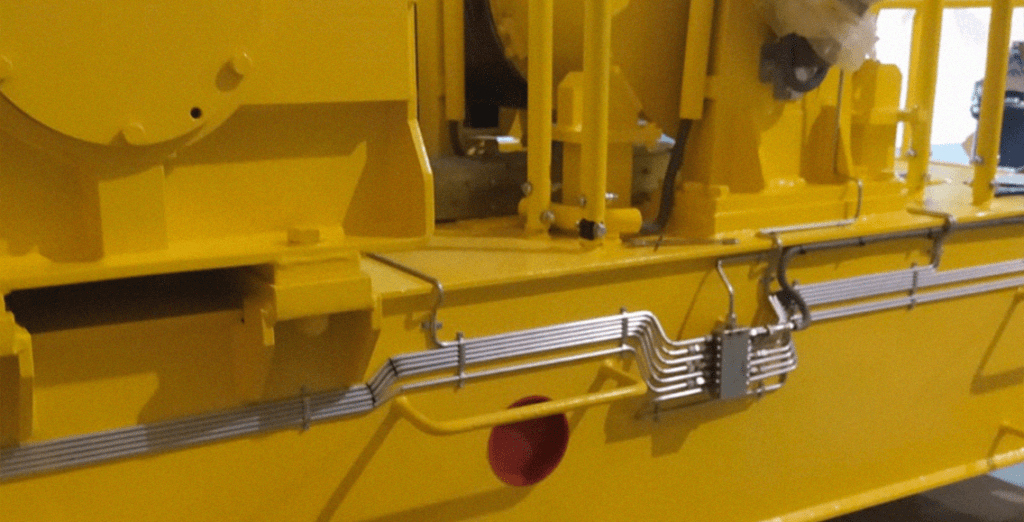

By closing one of the progressive distributor's outlets, the lubricant is distributed to the next lower outlet. This feature provides an enormous amount of dosing possibilities. A special feature of progressive lubricant dosing is that the previous feed line must distribute lubricant before the next one is supplied.

Progressive distributors must be able to be used without problems at high pressures (up to 100 bar differential pressure between two outlets) and for a very wide range of temperatures, with a maximum working pressure of 350 bar.

In case one of the pistons is blocked, this will cause all others to stop, too. External obstructions in the supply pipes to the consumption points, causing the flow to stop, will also cause the system to stop.

This property allows electrical monitoring of these facilities

Advantages:

- Economical and reliable.

- Exact lubricant dosage.

- High operating pressure.

- Visual or electrical control of the entire system.

- Effective even in severe conditions.

- Easily expandable by adding pumping elements.

- Versatile.