Lubrication

systems and equipment

fluid technology

Varnish control and removal from oils

Front page » Systems » Varnish removal from lubrication and hydraulic oils

Rivi has signed a distribution agreement with Fluitec to be its distributor in Spain starting from 2019

We all want to increase reliability, reduce downtime and maximize our assets' life. Is this an impossible feat to achieve? Definitely NOT, if special considerations are taken into account when designing maintenance tasks related to your equipment. If maintenance tasks are developed with the intention of not only maintaining assets, but also improving the overall reliability of the system, then this task is no longer impossible.

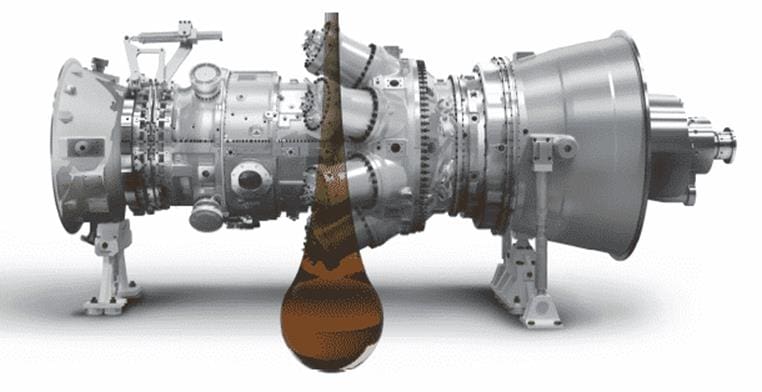

Improving your rotating equipment's reliability

Each system is made up of its mechanical parts, the systems responsible for its operation and its inputs and outputs. On most rotating equipment, we have control over the inputs to the system and we ensure they meet the requirements. We can also guarantee that the types of materials used for parts are of the highest standard or made for specific environmental factors. However, the systems responsible for the operation are those that have the greatest effect on the overall reliability of the equipment.

When we think of operating systems, we may think of the computer's control panel, but these go much further. Actual operating systems are the systems that are responsible for governing the computer's operation. This can also include human interactions with the equipment as they monitor its operation. For this article, we will examine the role of lubrication in the equipment's operation and its impact on the reliability.

Lubrication as an operating system

When lubricants are used in equipment, they perform five main functions:

- lubrication

- cooling

- cleaning

- heat dissipation

- wear minimization

All of this affects the way the equipment operates. If a lubricant does not perform any of these five functions, the equipment may operate at higher temperatures, which will greatly reduce the overall efficiency of the systems. Something similar happens when the oil oxidizes and produces varnish.

With the presence of varnish, systems are coated with these insulating layers that trap heat and restrict oil flow, especially at small clearances. Therefore, by keeping the oil in healthy condition to avoid the formation of varnish, we can increase the reliability of assets. Rotating equipment is the usual victim of varnish due to the conditions in which the equipment operates. Therefore, the reduction of varnish on any rotating equipment will lead to an overall increase in its efficiency.

This is a common question throughout the industry: Is there a magic cure for turbine, compressor or gear oils that ensures they are not susceptible to varnish? The short answer is: “Yes, let me explain.”

Our partner FLUITEC has developed a product called Solvancer® (a patent pending technology). This is a solubility enhancer that works on the “like dissolves like" principle. This means that Solvancer®, which is polar in nature, can dissolve varnish, which also has polar properties. Solvancer® has been integrated into the following products: DECON (in the form of DECON AO, DECON AW), Boost AO, Boost VR+ and Infinity TO.

How can we prevent or remove the varnish?

The product line DECON has been formulated to decontaminate equipment by rapidly dissolving varnishes and organic deposits. This may reduce the potential varnish in oil and offers long-term protection against deposits and sludge. DECON is generally added to in-service oils at a treatment rate of 3-5% and leaves no residue when it degrades. Essentially, DECON can prevent varnish through decontamination of oil in equipment. DECON AO has an additional formulation that rebalances the level of antioxidants for oil in service while providing deposit control.

On the other hand, DECON AW has been designed for hydraulic oils. It rebalances antioxidant and anti-wear packages for these oils in service, as these are the main weak points for hydraulic users.

Through the use of DECON AO or DECON AW, rotating equipment can reduce the number of failures experienced due to the presence of varnish. By keeping the system clean and free of varnish, it can now operate at maximum efficiency and this will reduce any downtime that may have taken place. Generally, if varnish occurs within a system, it will accumulate in layers inside the computer. For rotating equipment, particularly those with shafts, these layers of varnish can cause shaft misalignment, which in turn affects the equipment's operating efficiency.

Furthermore, when the varnish accumulates on this type of rotating equipment, it is not easily removed. These layers can bake inside the equipment and, unless the operators manually clean the system or rinse it (with an aggressive rinse), the varnish will stay. This can contaminate the new oil entering the system and increase the production of varnish. Although the varnish production rate is increasing, the efficiency rate of the machine will decrease due to valve sticking, line clogging, and even increased temperatures and vibrations. All this leads to a decrease in reliability that can be avoided by using the DECON product line.

Infinity Turbine Oils (Infinity TO) is an oil that was designed to be used in turbines or compressor systems so that it lasts as long as the equipment. Formulated with Solvancer, Infinity TO is designed to deny the formation of varnish products. After going through a series of simulated stress tests, the product created virtually no byproducts of varnish! Additionally, this product has a 10-year tank control performance guarantee. This guarantee ensures that the MPC level remains within the normal range (below 20) for ten years.

Maximizing your assets' lifespan

Typically, mineral turbine oils only last 3 to 5 years. This number can even be reduced to one year in the presence of heavy varnish or deposits. The turbines also have larger crankcases and the turbines will regularly undergo at least three oil changes over a ten year period. When we think about the downtime due to equipment shutdown, cleaning and startup of the turbine after a shutdown for this reason, this value can easily reach thousands of Euros. Imagine multiplying that number by three over the ten-year period! This is where operators can see the real value of switching to Infinity Turbine Oils, where they will not have these expenses for 10 years.

Increased reliability

When we talk about increasing your equipment's reliability based on its lubrication, one of the main ways is to keep the oil clean and free of varnish. This can be achieved by adding DECON or Boost to your oil in service. These products can be added in a ratio of 3 to 5% and are compatible with most oils. With them you can:

- Restrict the formation of varnishes

- Rebalance particular additive packages

- Keep the oil in optimal condition

Furthermore, if combined with Fluitec's ESP system, it can further extend the oil's lifespan and reduce any unplanned downtime.

Another option would be to protect the asset from the start by using Infinity TO at the next oil change. This can prevent varnish from forming within the system, allowing the equipment to reach its maximum reliability potential depending on the oil.

These are just a few of the ways you can increase the reliability of your rotating equipment assets. The real increase in reliability comes when we keep systems clean, healthy and functional. This can be done by combining a condition monitoring program that not only monitors the health of the assets, but also allows operators to make decisions regarding asset maintenance.